Last updated: 13/05/2025 01:00:45

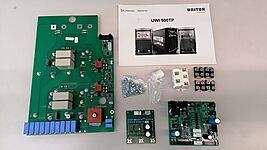

UWI-500TP WELDING INVERTER

Product Code

- Product group:

- 191

- Product number:

- 500500

UWI-500TP is a powerful welding inverter for all arc welding (Stick/TIG/MIG/MAG) & gouging processes onboard. Ideal for vessels requiring high duty cycle welding using very long welding cables extension especially deck maintenance etc.

Product information

This product supersedes product no: 670398

EU Ecodesign Compliant Welding Machine

The welding machine is supplied "without" any accessories. To order, include Part No. 670406 ACCESSORIES KIT F/UWI-230,-320,-500.

Features

- Stick electrode (MMA) with adjustable hot start and arc force for optimal welding properties

- Lift-Arc TIG welding with remote control option for all welding processes, with total arc control both during welding and for the down-slope finish of the weld. Adjustable gas post-flow prevents faults in the end phase of the weld

- Two machines can be linked in parallel for up to 1000 Amperes for Air Carbon Arc gouging

- Voltage Reduction Device (VRD) function reduces open circuit voltage to only 9VDC which reduces risks of electric shock and electrocution to the lowest level

- Built-in Total Protection (TP), Line-voltage compensation and Thermal overload protection

- Made of high-grade aluminium casing that reduces weight and corrosion risks

Benefits

- Safe and compliant welding machine for maritime use

- Heavy duty and superior reliability in tough maritime environment

- 5-500A current range covers the use of any size of welding electrodes and two machines can be connetced parallel to provide 1000A

- Multi-process welding with combination of UWF-102 Wire Feeder for wire welding

- Spare part kit available easy repair and to minimise downtime

Specification

General

| Invent Hazard Material (IMO/EU) classification | D-1 |

|---|

Dimensions/Weight

| Dimensions L x W x H [mm] | 670 x 290 x 510 |

|---|---|

| Weight [kg] | 47 |

Technical data

| Duty cycle [%] | 50 at max current |

|---|---|

| Ingress protection | IP23S |

| Recommended fuse [A] | 32 A slow |

| Voltage [V] | 3 phase 380-440V 50/60Hz main supply |

| Welding current [A] | 5-500 |

Documents

Related products

Accessories

**Required UWI-500TP accessories kit for stick electrode welding. **

Is accessory to

**Required UWI-500TP accessories kit for stick electrode welding. **