Navigating Through New Mooring Guidelines

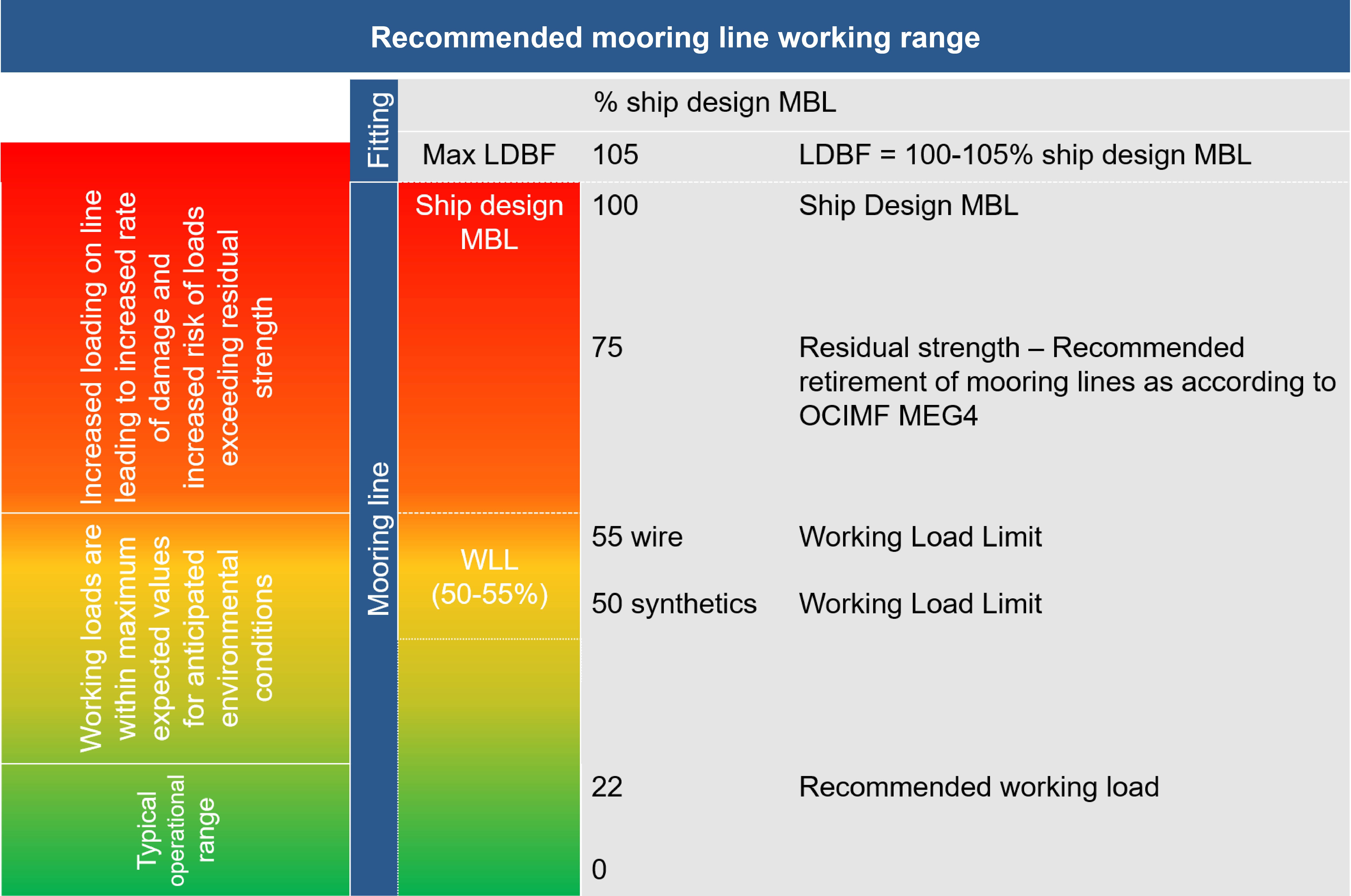

OCIMF has issued a new mooring equipment guideline, establishing new generic terminology, together with new test methods and rope management recommendations. Wilhelmsen Ships Service provides technical rope expertise and MEG4 certificates for Timm ropes, following recommendations from the fourth edition of the OCIMF Mooring Equipment Guidelines.

Fourth edition of the OCIMF Mooring Equipment Guideline

The Oil Companies International Marine Forum (OCIMF) has published the fourth edition of the Mooring Equipment Guidelines (MEG). These guidelines are considered as the state-of-the-art mooring guidelines that exist. Since the previous edition of MEG was released, there has been an increased focus on safe mooring, grown in correlation with the size and complexity of new, modern vessels. OCIMF MEG4 gives an insight into mooring from start to end, covering the full mooring operations and the rope's life time – providing mooring guidelines for safe mooring operations.

What is new?

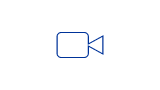

Mooring ropes are affected by many forces such as wind, current, tides, waves, swell, loading conditions, and interactions from other ships. If the mooring ropes are not used in accordance with the forces working on the lines, it can be a dangerous hazard for the crew working onboard the vessel, but also those standing on the quayside.

The new OCIMF Mooring Equipment Guidelines is now released in its fourth edition, and it is clarifying many of the confusions about mooring that were established in the industry. With new certificate templates and test methods, a uniform way of working with mooring ropes has been established across the industry.

Rope Management Tools

OCIMF MEG4 is establishing a foundation for a long-wanted system for rope management support tools. MEG4 gives a guidance on developing a Line Management Plan, which includes records or mooring hours, inspection records and plans, retirement criteria, reports, and manufacturer’s recommendations for the rope products. The Line Management Plan is a part of the Mooring System Management Plan, which will ensure that the mooring system is inspected, maintained and operated in accordance with the original mooring design basis of the vessel.

On this page, we have collected our manufacturer recommendations according to the new OCIMF MEG4. If you have any enquiries with regards to OCIMF MEG4, please feel free to contact us.

Technical Updates

-

Intelligent Mooring with Timm™ Smart Ropes

Offering exact load information, in real-time, our Timm Smart Ropes system revolutionizes vessel mooring.

-

Lifespan of Ropes

Determining the exact lifespan of a rope can be difficult, as there are numerous factors that can influence how long a rope can be used on board a vessel. In this article, the factors that affect a rope's service life and actions you can take to prolong the rope's lifespan will be discussed.

-

Replace Ringtails With Single Tails

With new testing for the entire mooring system, Wilhelmsen Ships Service recommends replacing ringtails with single tails. This article aims to give you relevant information on the attributes of ringtails and single tails, and their performances on new tension tests designed for whole mooring systems.

-

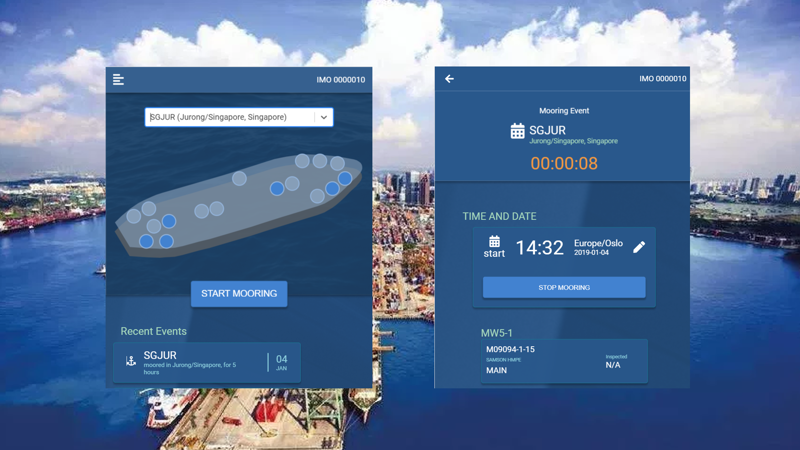

Line Management All in One Application

The Line Management Application provides a complete overview of the mooring equipment and usage onboard in just one App - working seamlessly across all devices; computer, phone or tablet - both on board and on shore. Click through for more information.

-

New Ropes Load Test

Timm™ Load Test is an OCIMF MEG4-compliant strength test of new or used ropes, determining a rope’s breaking load in addition to performing a stiffness test. Click through for more information.

-

TAC and OCIMF Certificate Flyer

Wilhelmsen Ships Service performs the full test scenario as per OCIMF MEG4, and our ropes come with TAC and OCIMF Certificates. Read more here.

Our Solutions

-

Conventional Ropes

Conventional ropes offer cost effective solutions. These floating, flexible and easily handled products have long been admired as premium mooring ropes.

-

High Performance Ropes

Our aim is to change the market dynamics for high performance ropes. Acera™ genuine HMPE ropes are stronger than steel, with 1/7 of the weight – and 1/3 of a same strength polyester rope weight.

-

Stretchers

Mooring tails are used to protect the mooring lines and to allow ships to sway and move with the environment. Our Mooring tails are typically used with steel wire and HMPE ropes, providing shock/energy absorbing within the mooring system.

-

Rope Protection

These high tenacity guards are suitable for all fibre rope types. Chafe guards can be easily installed and can provide an instant defensive barrier against sharp surfaces and edges. The Timm Chafe Guard is highly resistant to mineral acids, alkali, electrolytes, oxidising agents and remains stable in aqueous acids and non-polar solvents.

-

Onboard Ropes Inspection

We offer visual inspections of mooring ropes on board your vessel, providing inspection reports and recommendations for your mooring lines and arrangements.