Changing the game in mooring ropes safety

Wilhelmsen insights

|

Veronika Aspelund , Business Manager, Ropes

Mooring operation is one of the most common activities at ports and terminals, and also one of the most dangerous aspects of vessel operations.

Rope and wire-related mishaps are responsible for 95% of personal injury incidents in the maritime industry, with 60% of them happening during mooring operations, according to the European Harbour Masters’ Committee. These incidents usually lead to severe accidents, or even deaths.

Over the years, regulators have been actively reviewing and updating rules and guidelines to reduce the number of such accidents. With this heightened emphasis on safety, industry players are also continuously exploring safer ways to mitigate the dangers associated with mooring operations.

Mooring ropes are critical in any circumstance when a vessel is docked in a port or terminal. When high winds and poor weather are thrown into the mix, a catastrophic situation may emerge. While the ropes are designed to withstand a certain force, they are supposed to have a breaking point to prevent damage on the bollards, mooring equipment, and ultimately, the ship.

Every type of mooring rope has a snap back in case of breakage. Should the rope under tension break, energy is released, and as a result, it will flail uncontrollably, striking everything in its path at extraordinary speed and force.

When a mooring rope holding a docked vessel snaps, the abrupt energy release can cause the rope to whip across the dock and ship at a speed of almost 800km/h. Snap back accounts for an astonishing 53% of mooring accidents, with 1 in 7 of them resulting in fatalities, according to the UK P&I club.

To provide a safer mooring environment for all seafarers, Wilhelmsen has developed comprehensive mooring solutions. The Snap Back Arrestor (SBA) is one such innovation that has been designed to reduce the risk of snap back.

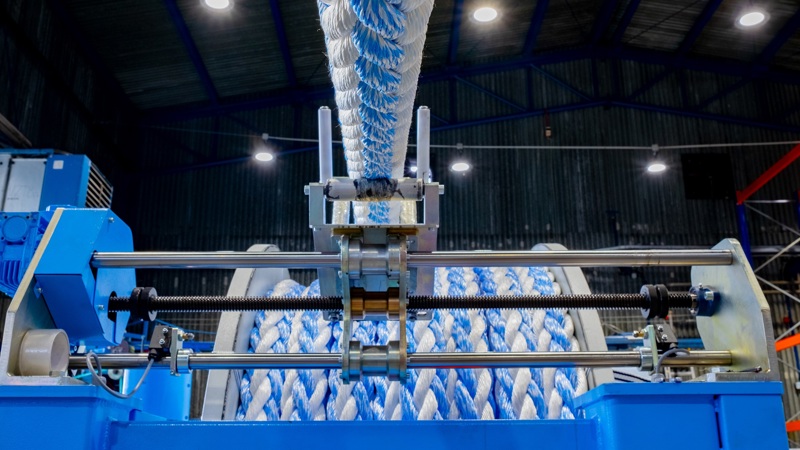

SBA ropes under production

These ropes, made from HMPE yarns or mixed composition (Polyolefins/HT PES), offer superior strength-to-weight ratio and abrasion resistance. Before being introduced to the market, they undergo a rigorous research and development (R&D) process. They are fully developed and tested in Wilhelmsen’s testing facility in Slovakia, certified and verified by DNV, then meticulously tested in real-life simulations in Flekkefjord, Norway where the performance of ropes with SBA was compared to ropes without SBA.

Real-life simulations in Flekkefjord, Norway

Following many rigorous trials, the SBA ropes were formally released and integrated into Wilhelmsen’s entire product line in 2019. Their effectiveness in preventing major accidents has been endorsed by shipowners, crew, port terminal personnel, and other stakeholders as a gamechanger in the maritime industry.

How the SBA feature safeguards Kassian Maritime's crew

Here is a recent real-life example that testifies to the effectiveness of the SBA feature in preventing injuries.

Kassian Maritime Ltd is a renowned sea transportation services operator based in Greece. On 12 September 2021, while one of Kassian’s Panamax Bulk Carriers was berthed alongside Acajutla (El Salvador) discharging cargo, she was subjected to severe longitudinal and transverse swinging due to gale force winds and high swell entering the unprotected port from the open sea.

As a result, four sets of its mooring ropes gave way and snapped. Fortunately, all four were Wilhelmsen’s Timm Master 12 SBA ropes, the safest conventional mooring rope on the market. The Snap Back Arrestor feature of the ropes had successfully prevented them from completely breaking at great speed, which reduced the impact that would have caused serious damages to both personnel and property.

“Fortunately, our company’s policy of adopting a uniform scheme of Wilhelmsen’s SBA ropes across the entire fleet proved to be a wise decision,” says Mr. Demponeras, General Manager-Technical Director of Kassian Maritime Ltd. “The Snap Back Arrestor feature of the mooring ropes worked excellently, resulting in the prevention of severe injuries for our crew.”

Broken ropes with the SBA still intact. This feature prevented the ropes from highly dangerous snap back.

“We are very proud to see the results of our hard work,” says Veronika Aspelund, Business Manager, Ropes in Wilhelmsen Ships Service. “It is a fact that some ropes onboard vessels will break. In some cases, breakage can be prevented through better maintenance or timely rope replacements, but in many cases, incidents are unpredictable. Contributing to preventing injuries onboard and even saving lives is the key purpose of our SBA ropes. We are very glad that Kassian Maritime reaped the benefits of this innovation, and are even more pleased that were no injuries or lives lost.”

At Wilhelmsen, user safety continues to be a key priority, and the company is keen to see more industry players focus on this aspect. To this end, Wilhelmsen is currently collaborating with various stakeholders across the industry, such as terminals, organisations, unions, and class societies, to increase equipment safety standards and the availability of safety equipment across the industry.

Veronika continues, “We want more suppliers to be able to offer safer solutions to the industry, and for customers to be assured that the solutions offered actually perform as they should, giving seafarers peace of mind throughout their journey.”