Innovation

Embracing sustainable innovation through new technology and finding new ways of working are essential for us to continue shaping the maritime industry. We are not a tech company, but technology-driven to improve our offerings to customers and the maritime industry as a whole.

Our approach to innovation is to invest and develop new business models, technologies, processes and capabilities that result in sustainable product and service offerings, and the enabling infrastructure. Sustainable innovation is required to address the challenges of energy transition and decarbonisation of shipping and meet the needs of our customers for their daily operations.

|

UNSDG |

Target 2020 |

Result 2020 |

Target 2021 |

|

We innovate to bring the latest technology to assist ship owners with meeting their goal of reducing carbon footprint. |

Wilhelmsen has been awarded the Hyship project to focus on development and commercialization of hydrogen as a carbon-neutral fuel.

Delivery of Yara Birkeland, first autonomous vessel, through Massterly. |

Continue to progress on Wilhelmsen group's investments, projects and other innovations in line with the group strategy. |

Development of Hydrogen for marine applications

Hydrogen is light, storable, energy-dense, and produces no direct emissions of pollutants or greenhouse gases. In order to decarbonize the shipping sector, hydrogen can be used to progressively replace fossil fuels on vessels.

In 2020, Wilhelmsen led a Europe funded project call Hyship – a consortium of 14 European partners who will demonstrate liquid hydrogen as fuel. This project has been awarded US$25 Million by the Norwegian government-owned organization Enova.

Project feature:

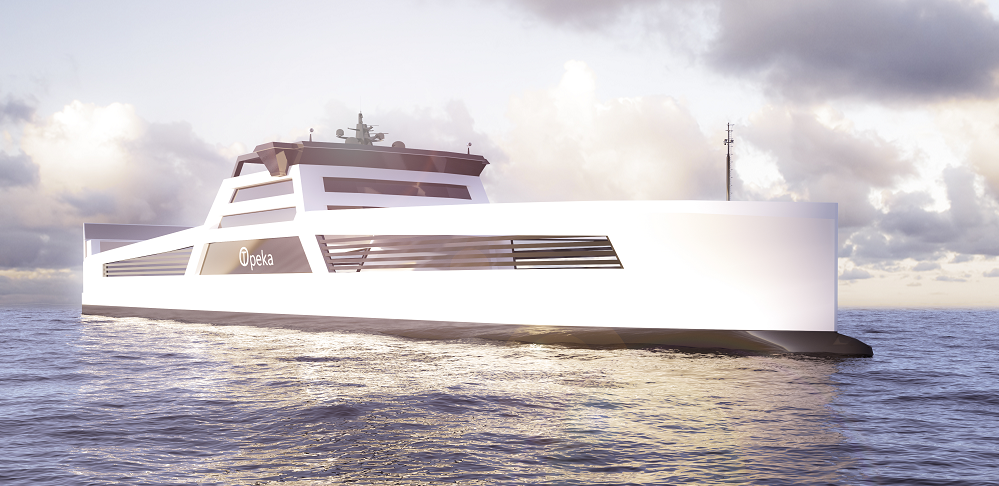

Topeka is a zero-emission prototype vessel running on liquid green hydrogen. The prototype is designed as an open-deck roll-on/roll-off (RoRo) vessel, the 2,500m2 vessel is capable of handling containers and trailers carrying both liquid and compressed hydrogen. The prototype will run on a 1MWh battery pack and a specialized 3MW hydrogen fuel cell charged by power from the shore.

Battery operated vessels

Wilhelmsen Ship Management aims to be the world's first ship management company to operate unmanned electric vessels for

commercial use.

In November 2020, the world's first autonomous cargo vessel made her maiden voyage. Wilhelmsen is one of the reason why this vision became reality. Since 2017, Wilhelmsen, in partnership with Yara and Kongsberg, jointly developed this concept into reality. The Norwegian Government awarded a grant of NOK133.6m towards the construction of the ship; about a third of the total cost. A vessel remote control centre has been established in the Wilhelmsen headoffice for the management of Yara Birkeland.

Project Feature:

Yara Birkeland is a zero emission container vessel, 80 metres (260 ft) long, with a beam of 14.8 metres (49 ft) and a depth of 12 metres (39 ft). It will have a draught of 6 metres (20 ft). It is propelled by electric motors driving two azimuth pods and two tunnel thrusters. Batteries rated at 7.0-9.0 MWh power the electric motors, giving it an energy optimal speed of 6 knots (11 km/h) and a maximum speed of 10 knots (19 km/h). It has a capacity of 120 TEU. The vessel will initially undertake manned sailings, gradually switching to fully autonomous mode by 2022.

In 2020, Wilhelmsen have been selected by the leading Norwegian food grocery distributor ASKO to operate two new vessels equipped with autonomy technology from Kongsberg Maritime. The vessels will be equipped with the technology required for zero emission and unmanned operation by Kongsberg Maritime while Wilhelmsen oversees ship management and safe operations from their shore-based Remote Operations Centre.

Project Feature:

The ASKO vessels are RORO (Roll on, Roll off) vessels measuring at 66 metres long, with a beam of 15 metres that can load, carry and discharge 16 EU-spec trailers. The vessels are constructed in accordance with the rules and regulations of DNV GL Classification Society with the Class notation: 1A1 + Battery Power + RP (1,40) + R3 + General Cargo + BIS. Vessel construction is taking place at the state-owned Cochin Shipyard in India. Both vessels will initially operate with reduced crew from 2022, before moving towards unmanned voyages.

AS A LEADING SHIP MANAGER, WE UNDERSTAND THE NEED TO IMPROVE AND INNOVATE THROUGH NEW TECHNOLOGY AND NEW WORKING METHODS.

-

Spark by Wilhelmsen Ship Management

There are many complex energy efficiency solutions on the market, however not one with the end-user in mind. Using this as a starting point, we embarked on the development of Spark – an intuitive application which adds value to the customer.

Read more about Spark -

Data automation to deliver greater customer experience

Operational efficiency is the fundamental pillar of our business strategy. We are fanatics in looking for ways on how we can work better and efficiently by using our available technology to deliver more value to customers.

Read about our data automation journey -

Cut to the chase with sea-shore transparency

Internet of Things (IoT) is one of the most exciting development in shipping technology. Today, we harness the power of real-time data onboard to make informed decisions that improve vessel operational efficiency while reducing operating expenses.

Read about how we move towards a data driven future