To avoid the damage and dangers caused by refrigerant leaks, it is extremely important to follow the recommendations below to ensure that the leak monitoring system is functioning accurately.

- Replace visibly damaged monitors and detectors immediately.

- Check and test the detectors once every 12 months with the diagnostic tool DT300

- Required by Safety Standard for Refrigeration Systems, EN378:2016.

- Replace the sensor every 5 years

- Under normal circumstances, the lifetime of the sensor in the detector is up to 5 years. As a preventive measure, we recommend that ship owners plan for sensor replacements when it reaches 5 years in operation.

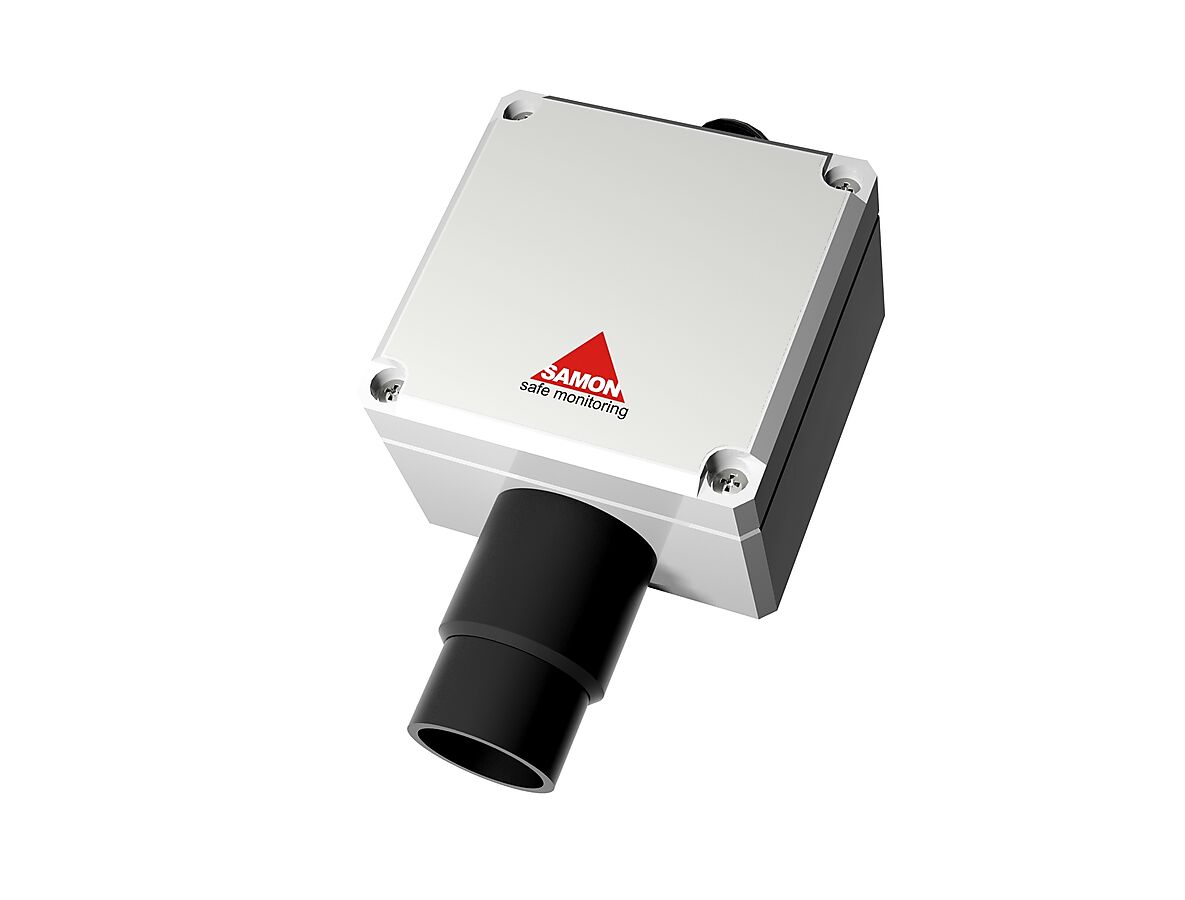

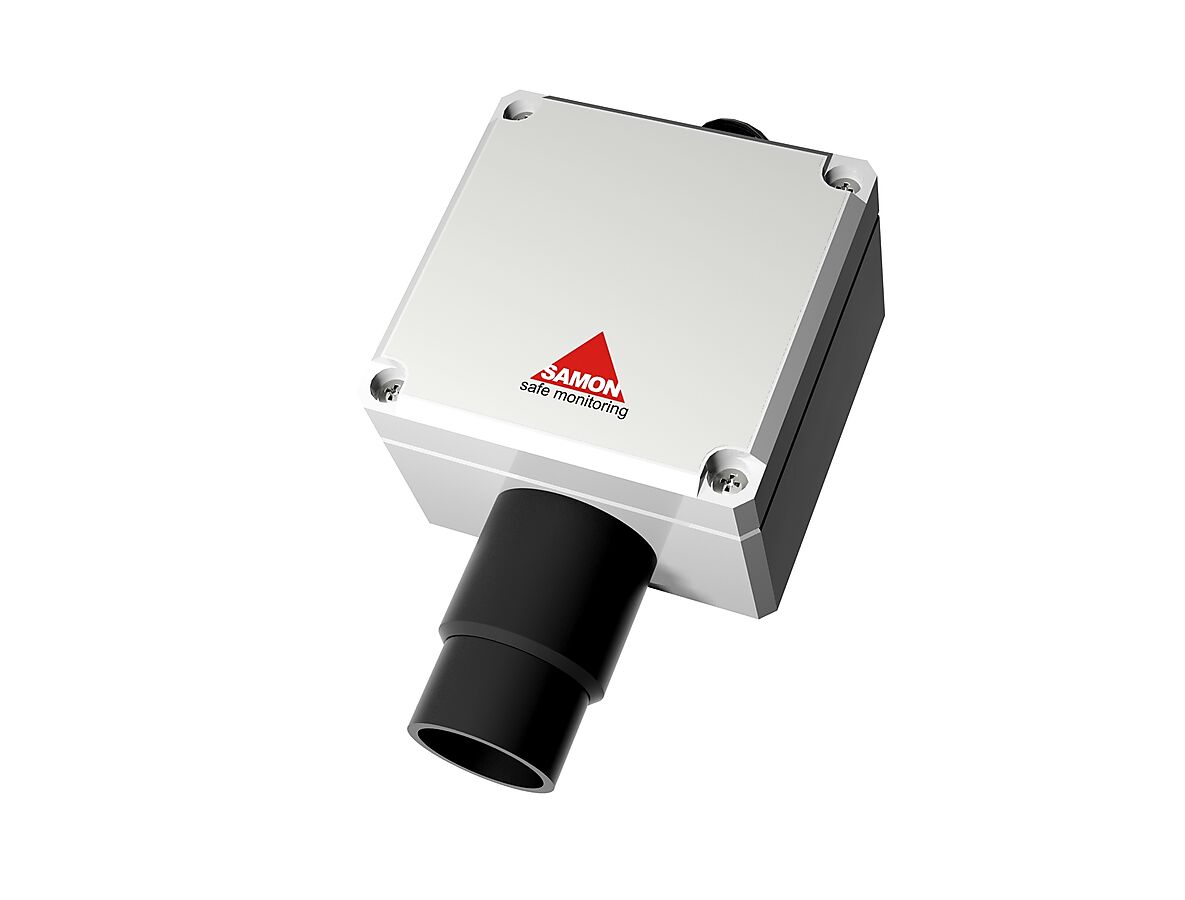

This detector comes with the new sensor, SEN027 (SELF SENSE) with a built-in filter that makes the sensor much more resistant to false alarms caused by dust, dirt, liquids, and aerosols.

The change of SEN027 can be performed without any change in alarm settings, and calibration is recommended with the DT300 and SM300-SELF SENSE sensor module.

Benefits

Safety of crew members - round the clock monitoring and alarm. Alerts ship crew in case of emergency.

Cost-saving - Minimise refrigerant loss and reduce operating costs.

Time-saving - Product and spares can be delivered together with other marine products from WSS.

Regulatory compliance - Complies with major regulatory bodies such as F-gas Regulation, EPA, Marpol Annex VI, LR ECO Class notation and ABS ES Notation.

Environmentally Friendly - Enables early detection and minimise the release of harnly GHGs into the atmosphere.