Protect your vessel’s potable water systems from corrosion and contamination

Wilhelmsen insights

|

Han Ding Hou, Global Product Marketing Manager - Water Solutions

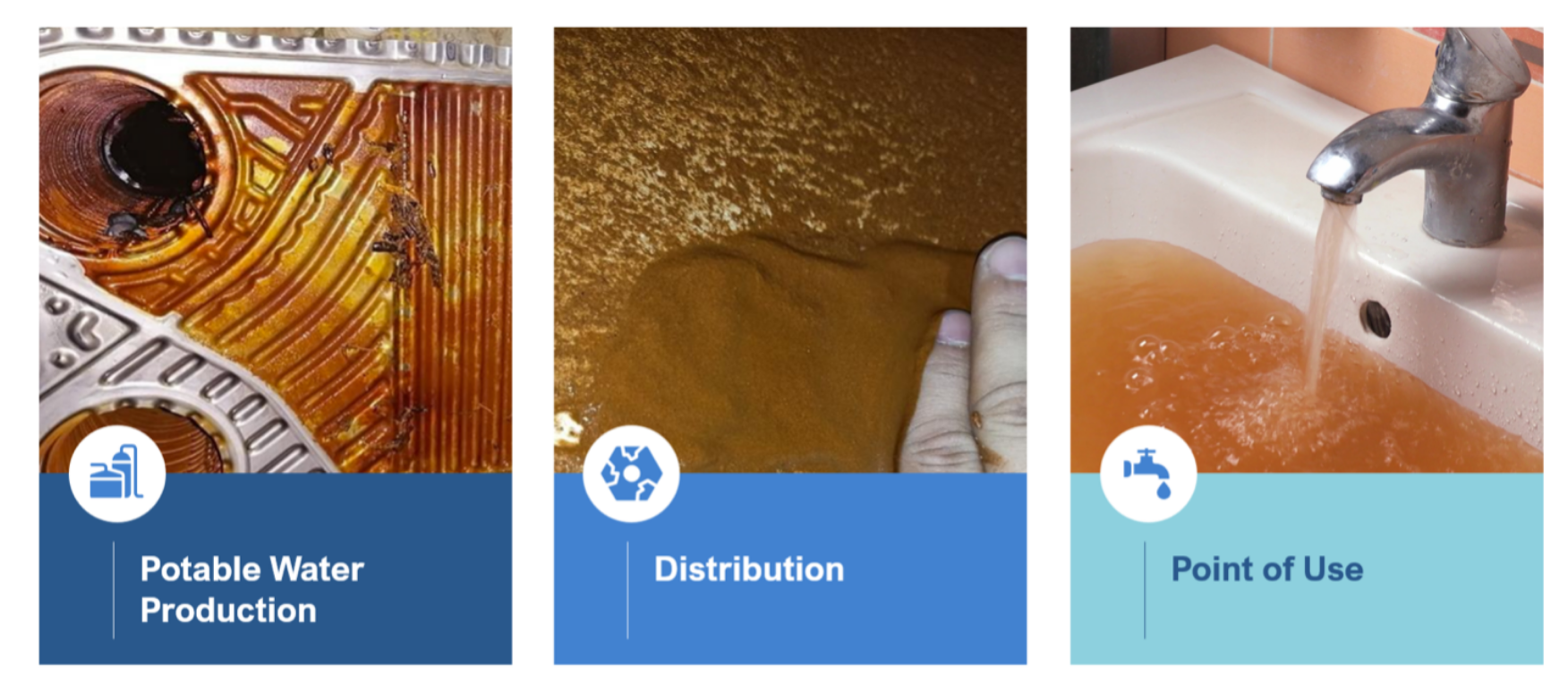

Freshwater on board is more than just a comfort — it’s a critical lifeline for crew health, operational safety, and compliance. Yet, many vessels face persistent challenges with corrosion, biofouling, and water quality degradation in potable water systems. These issues don’t just affect taste or appearance; they can lead to costly pipe replacements, health risks, and potential detentions during inspections.

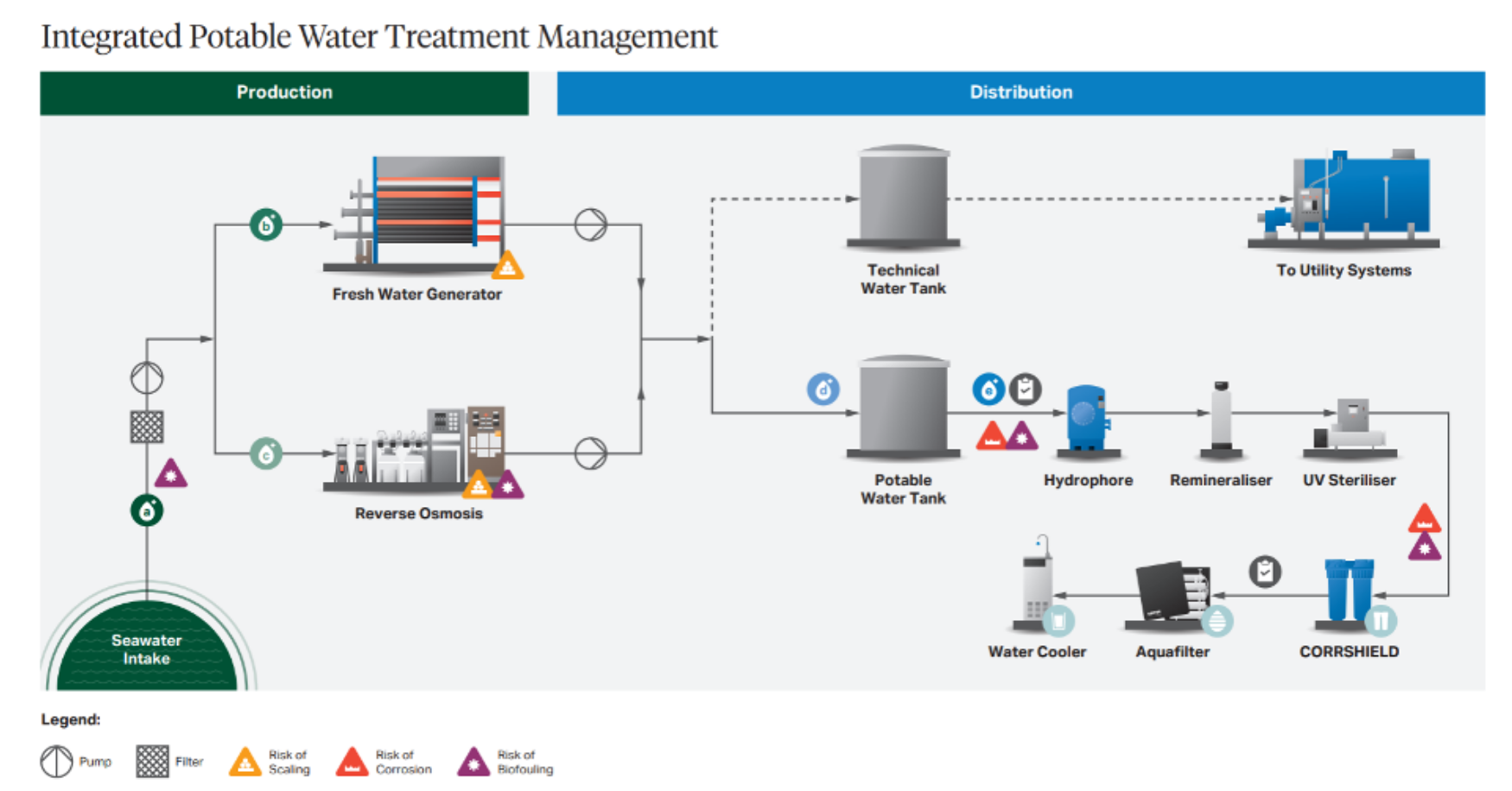

Wilhelmsen’s Integrated Potable Water Management (IPWM) approach is designed to address these challenges from the moment water is generated or bunkered, through storage, distribution, and consumption — ensuring that every sip meets the highest standards for safety, taste, and compliance.

What’s the core challenge with shipboard potable water?

Onboard potable water systems are vulnerable. Even minor contamination—from tank fouling, pipe corrosion, or inadequate disinfection—can degrade water quality, risk health, and trigger regulatory flags. The “Clean Potable Water” page highlights how neglecting chemical protection or using non-potable-safe dosing products can lead to microbial growth, off-taste, or health hazards. Effective management means treating every part of the system—from generation to distribution—while keeping crew safety front and center.

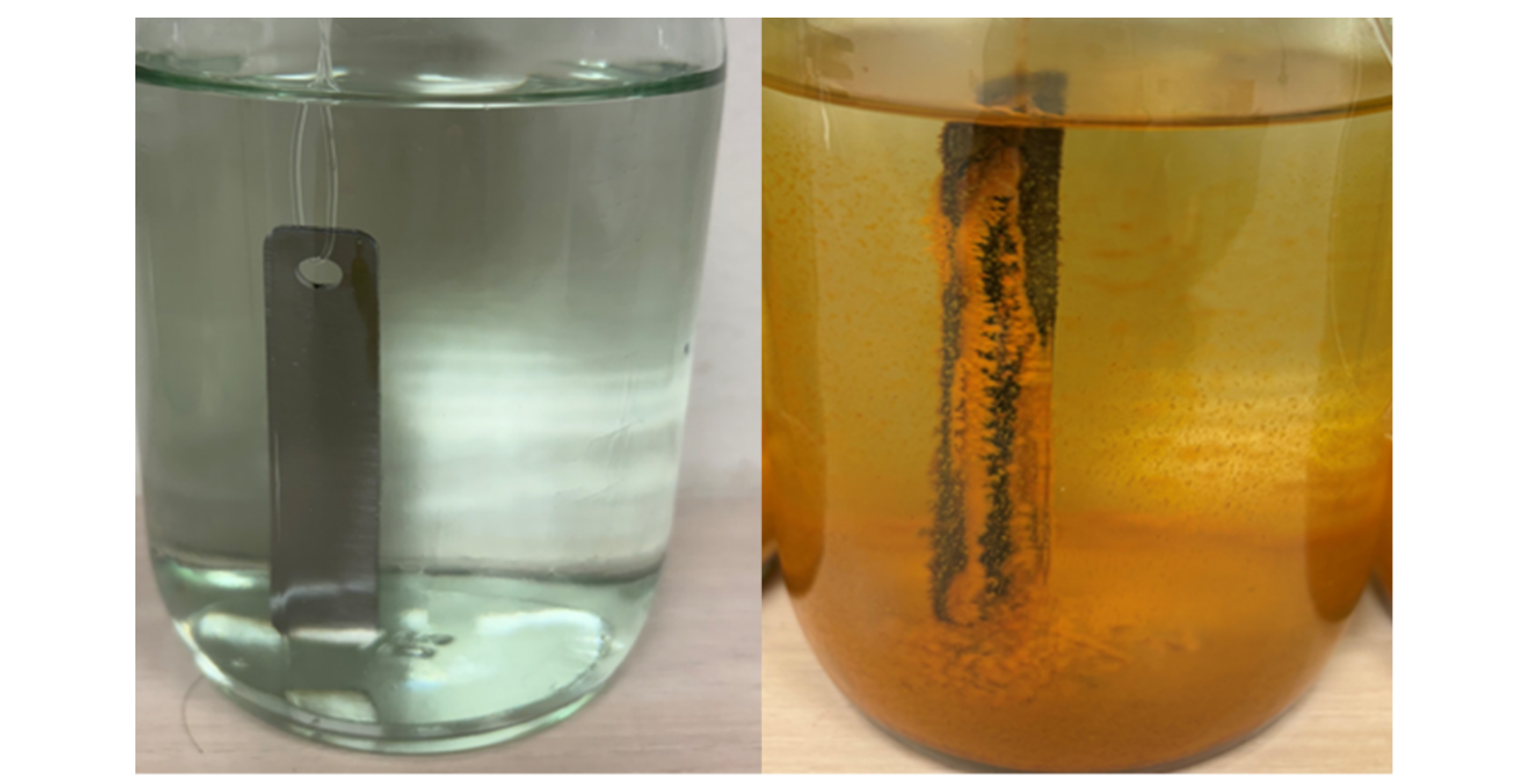

What do these problems look like—and what are the hidden costs?

You might notice a metallic taste, cloudy water, or stained fixtures, but these symptoms signal deeper issues. Biofilms and scale lead to blocked filters, inconsistent delivery pressure, or expensive tank and piping clean-outs. Unchecked microbial growth increases the risk of Legionella or other pathogens, which can result in PSC detentions or illness. Beyond crew health, these failures can cause extra chemical costs, lost work time, third-party inspection failures, and reputational risk.

Why do potable water issues linger onboard?

- Lack of Awareness: The current potable water quality assurance focus on microbial control ignoring latent operational, safety and energy efficiency impact from improper corrosion and scaling management

- Inconsistent water quality: Shore-supplied water varies widely in biological load and disinfectant residual.

- Suboptimal dosing: Without precise, potable-safe chemicals and accurate monitoring, chlorine or pH drifts out of the safe band.

- System design and stagnation: Pipeline metallurgy, poor layout, dead legs, or lack of circulation allow biofilm to flourish.

- Crew turnover & time pressure: Regular maintenance—even routine sanitization—gets deprioritized.

- Data gaps: Without real-time monitoring or records, anomalies go unnoticed until they escalate.

How does Wilhelmsen solve this with its potable water solutions?

Our IPWM model addresses these risks comprehensively:

- Drinking water treatment products compliance to established standards or certified to NSF/ANSI/CAN-60 providing quality assurance, corrosion, microbial and scaling control (e.g. Vaptreat, Reverse Osmosis product range, etc...)

- Digital monitoring via the WaterProof app ensures weekly test logging, dosing alerts, and regulatory archives.

- Expert onboarding: Teams provide tailored chemical programs, and dosing setups.

- Global availability: We've stocked potable-safe products in over 100 warehouses and deliver to 2,200 ports with 98% on-time reliability.

- A complete ecosystem: From seawater intake to potable water use, we provide treatment solution to address shipboard needs.

Best practices to keep potable water healthy onboard

- Always use certified/compliance, potable-safe chemical treatments for microbial, corrosion and scaling control

- Conduct regular cleaning and sanitization of tanks and line flushes before bunkering.

- Install inline dosing and flow-based controls, not just manual chemicals, with crew-trained test verification.

- Monitor key parameters (chlorine residual, pH, microbial levels) daily and document through WaterProof for alerts.

- Avoid stagnation by minimizing dead legs and using proper circulation and storage design.

- Maintain clear treatment logs, test records, and maintenance schedules to support ongoing oversight and inspection compliance.

Get in touch with our experts

Han Ding Hou - Global Product Marketing Manager

With over 18 years of expertise in water treatment, Hand Ding Hou brings deep technical and strategic knowledge across diverse applications, including boiler water, engine and cooling water, ballast water, potable water, and wastewater systems. His career spans global markets, where he has led product innovation, lifecycle management, and application development to optimize performance and sustainability. Han is recognized for driving solutions that meet stringent regulatory standards while delivering operational efficiency for industrial and marine sectors.