Last updated: 30/04/2025 05:21:56

U.V. TRACER KIT 12V

Product Code

- Product group:

- 606

- Product number:

- 711523

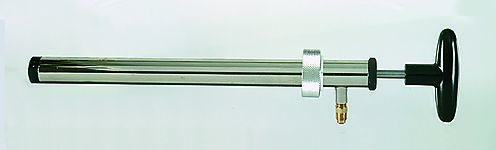

Effective tool for locating refrigerant leaks in refrigeration systems in inaccsessible areas by circulating the tracer fluid and using UV-light. A rechargeable battery gives complete freedom on where to use the kit.

Product information

This product supersedes product no: 596510

Glo-Leak tracer fluid is an oil based fluorescent liquid that is fully miscible and compatible with refrigerants and compressor oil. When added to the compressor oil sump, the tracer fluid circulates around the system with the compressor oil. Evidence of the tracer fluid will be found at the source of each leak. This will give a fluorescent glow when the area is scanned with the UV inspection lamp, easily identifying the location of the leak.

Features

- Oil based fluorescent liquid fully miscible with refrigerant compressor oil

- Circulates in system and leaves fluorescent trace if leak

- 110 V and 220 V charger included

- 12 V - 7 Ah battery gives a long operating time up to 30 minutes

Benefits

• Safety of crew members -- Enables ship crew to conduct safety checks from a distance and safeguards crew members from refrigerant poisoning.

• Cost savings -- Minimises refrigerant loss and ensures system is always operating in optimum condition.

• Environmental protection -- Minimises the release of environmentally-harmful substances into the atmosphere.

• Regulatory compliance -- In accordance with major regulatory bodies like EU F-gas regulation, EPA, DNV Clean Notation, LRS EP Notation, ABS ES Notation.

Specification

General

| Invent Hazard Material (IMO/EU) classification | D-1 |

|---|---|

| Product code | UV2165U+ |

Technical data

| Voltage [V] | 12 V operating |

|---|

Safety Data Sheet (SDS)

Documents

Directions for use

Dosing method

- Add the correct amount of Glo-Leak tracer fluid to the system (dosage rates as below). Glo-Leak may be added in one of the following ways:

- Directly into the compressor oil reservoir

- Via a standard oil charge pump

- Through the charging port on the compressor suction valve

- Operate the system for enough time to allow Glo-Leak to permeate all suspected leak areas. Some leaks may show up within minutes. Others may take hours or even days to reveal themselves.

- Scan the system to locate any leaks by shining the UV lamp supplied over all areas of possible leaks. The precise source of a leak is revealed by a fluorescent yellow or yellow-green glow.

- Once identified, repair the leaks.

- Clean off any excess Glo-Leak with Glo-Klenz (or with another suitable cleaner/degreaser).

Glo-Leak can now remain in the system so that regular leak checks during maintenance may be performed with ease. This should be done at regular intervals to ensure optimum performance.

Dosage and control 1. When the ratio of oil to gas is 1:3, add the fluid at the rate of 0.75% of the total oil charge. 2. When the ratio of oil to gas is more than 1:3, use the formula below. (Amount of oil x 0.01) + (gas charge in kg x 0.0015) = Amount of tracer fluid in ltrs.

Example: A refrigeration system contains 100 ltrs of oil and 500 kgs of refrigerant.

(100 x 0.01) + 500 x 0.0015) = 1 + 0.75 = 1.75 ltrs of tracer fluid

NB: The above dosage rates are conservative estimates. Different system capacities and designs, and the various lubricants available can vary the amount of Glo-Leak required, especially in large systems. Check for fluorescent brightness by shining a UV lamp at the sight glasses. Add more Glo-Leak if the glow is weak. In some large systems, it may be necessary to add extra Glo-Leak after a week. This is because there may be much more oil in the system than is specified by the compressor manufacturer