Product information

This product supersedes product no: 587170

The Refrigerant Leak Detection U.V. Tracer Kit (1.5V) is supplied with:

- Sturdy aluminium case

- SuperBright UV-LED Inspection Torch (400nm) with 3 AA batteries

- 4 bottles of Universal tracer fluid (250ml)

- Protective goggles (SP301UV)

- Biodegradable Solvent Spray Cleaner (250ml)

The UV Tracer fluid is an oil based fluorescent liquid

that is fully miscible and compatible with all refrigerants and compressor oils. When

added to the compressor oil sump, the UV Tracer fluid will mix with the lubricant oil

and circulate around the system. If there is a leak, the UV tracer fluids will come out on

the surface and they will be visible with yellow fluorescence glow under the UV light

Features

• The UV tracer fluid is suitable for all refrigerants and

compressor oils.

• SuperBright UV-LED Inspection Torch delivers brilliant

fluorescence and is able to effectively pinpoint the exact

location of the invisible leaks.

• Biodegradable solvent spray cleaner can remove UV

Tracer fluid residue and other stains effectively.

• Protective googles is DIN certified and conforms to

89/686/EEC, EN166 and EN170 (UV Protection), ensuring

that crew members stay safe while conducting leakage

checks.

Benefits

• Safety of crew members -- Enables ship crew to conduct safety checks from a distance and safeguards crew members from refrigerant poisoning.

• Cost savings -- Minimises refrigerant loss and ensures

system is always operating in optimum condition.

• Environmental protection -- Minimises the release

of environmentally-harmful substances into the

atmosphere.

• Regulatory compliance -- In accordance with major

regulatory bodies like EU F-gas regulation, EPA, DNV

Clean Notation, LRS EP Notation, ABS ES Notation.

Directions for use

Dosing method

- Add the correct amount of UV tracer fluid to the system (dosage rates as below). UV tracer fluid may be added in one of the following ways:

- Directly into the compressor oil reservoir

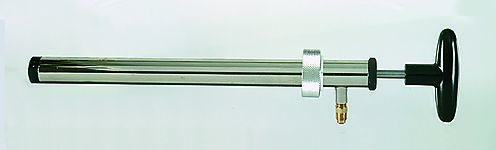

- Via a standard oil charge pump

- Through the charging port on the compressor suction valve

- Operate the system for enough time to allow the UV tracer fluid to permeate all suspected leak areas. Some leaks may show up within minutes. Others may take hours or even days to reveal themselves.

- Scan the system to locate any leaks by shining the UV lamp supplied over all areas of possible leaks. The precise source of a leak is revealed by a fluorescent yellow or yellow-green glow.

- Once identified, repair the leaks.

- Clean off any excess UV tracer fluid with Glo-Klenz cleaner (or with another suitable cleaner/degreaser).

The UV tracer fluid can now remain in the system so that regular leak checks during maintenance may be performed with ease. This should be done at regular intervals to ensure optimum performance.

Dosage and control 1. When the ratio of oil to gas is 1:3, add the fluid at the rate of 0.75% of the total oil charge. 2. When the ratio of oil to gas is more than 1:3, use the formula below. (Amount of oil x 0.01) + (gas charge in kg x 0.0015) = Amount of tracer fluid in ltrs.

Example: A refrigeration system contains 100 ltrs of oil and 500 kgs of refrigerant.

(100 x 0.01) + 500 x 0.0015) = 1 + 0.75 = 1.75 ltrs of tracer fluid

NB: The above dosage rates are conservative estimates. Different system capacities and designs, and the various lubricants available can vary the amount of UV tracer fluid required, especially in large systems. Check for fluorescent brightness by shining a UV lamp at the sight glasses. Add more UV tracer fluid if the glow is weak. In some large systems, it may be necessary to add extra UV tracer fluid after a week. This is because there may be much more oil in the system than is specified by the compressor manufacturer.