Last updated: 17/10/2025 01:00:48

FUELPOWER SOOT REMOVER 25 KG

Product Code

- Product group:

- 650

- Product number:

- 779115

Unitor™ FuelPower Soot Remover - Maximize Your Boiler Efficiency Your ultimate solution for maintaining a clean and efficient boiler. By effectively removing soot and ash deposits from your boiler's exhaust system, it extends the intervals between cleanings and ensures optimal performance.

Product information

If deposits are allowed to form on boiler heat exchangers, the loss of efficiency can be directly related to extra fuel consumption. A 1 mm deposit is approximately equivalent to a 10% efficiency loss, a 3 mm deposit can reduce efficiency by up to 50%. The normal ignition temperature of soot is around 600°C. This means that it is burned only in the hottest parts of the boiler or diesel exhaust systems. Due to the catalytic action of Unitor FuelPower Soot Remover, the ignition temperature of the soot/deposit is reduced to less than 280°C. The carbon deposits are thus ignited, leaving an easily removed ash. The use of Unitor FuelPower Soot Remover not only provides greater fuel efficiency, but also prevents acid formation in areas where severe corrosion could result in expensive damage, i.e. heat exchangers, superheaters, economisers, exhaust paths/stacks.

Features

- Reduces cold-end corrosion

- Assists soot blowing

- Keep boiler clean from soot and deposits

Benefits

- Longer time between cleaning intervalls

- Saves you money by improving heat transfer

- Saves you money by increasing boiler efficiency

Specification

General

| Invent Hazard Material (IMO/EU) classification | C-49 |

|---|

Physical properties

| Appearance | Blue green |

|---|---|

| Density [kg/m3] | 1,2 - 1,4 |

| Form | Dry powder |

Technical data

| Not Compatible | If moist, may attack mild steel, iron and aluminium |

|---|

Safety Data Sheet (SDS)

Documents

Directions for use

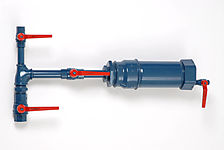

Dosage and control FuelPower Soot Remover should be introduced to the boiler through a suitable port, preferably with a blower, ensuring that the powder is spread through the flame path towards the back of the combustion chamber. For Diesel engines, inject FuelPower Soot Remover directly into the exhaust system upstream of the area to be treated. FuelPower Soot Remover is preferably dosed using Unitor's Fixed Injector, product No. 572073 and/or Portable Injector, product No. 572065.

Steam Raised (tons/hr) |

Boiler Fuel (tons/day) |

Dose Rate (kg/day) |

|---|---|---|

| Boiler | ||

| 3 | 5.5 | 1.0 |

| 6 | 11 | 2.0 |

| 9 | 16 | 3.0 |

| 12 | 21 | 3.5 |

| 15 | 27 | 4.0 |

| 23 | 41 | 4.5 |

| 31 | 55 | 5.0 |

| 46 | 82 | 5.5 |

| 62 | 110 | 6.5 |