Maritime authorities, such as the Norwegian Maritime Directorate, require the installation of flashback arrestors for acetylene and oxygen, as incorrect maintenance or use of gas welding equipment may cause flashbacks of various types.

Normally these will stop in a well designed torch, and are only noticed as a popping sound in the torch. However, faulty handling, maintenance or gas pressure setting may lead to a penetrating flashback. This means that the gas flame passes back through the hose(s). In some cases it may also pass the regulator and ultimately reach the cylinder.

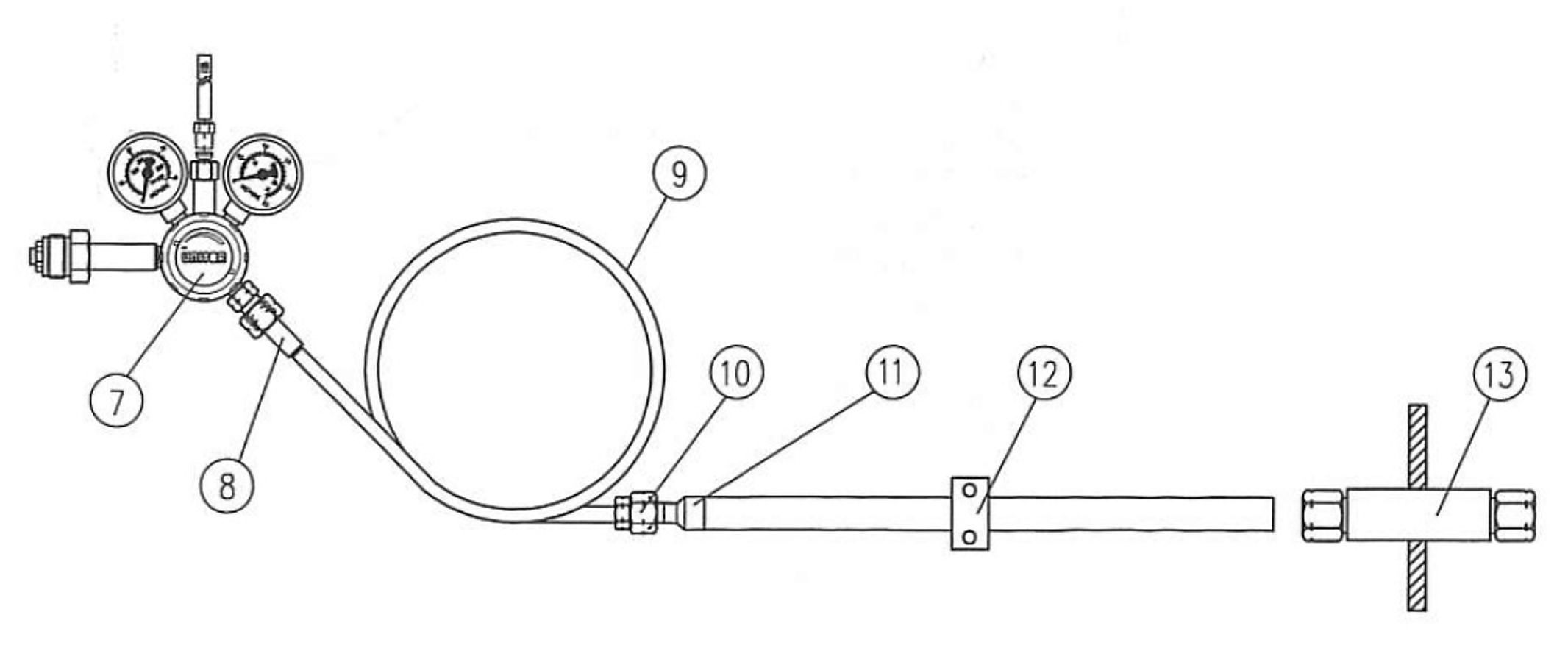

The flashback arrestors supplied by Unitor are designed for use both with gas cylinders and gas outlet stations and incorporate several safety functions:

- Non-return valve preventing reverse flow of gases, thereby preventing a gas mixture from reaching pipelines or cylinders

- Flame filter to quench the flame front of a flashback or a burnback

- Temperature activated cut-off to prevent further gas supply in case of fire (activated if the temperature rises to approximately 100° C).

- Pressure activated cut-off to prevent further gas supply after a flashback (activated by the pressure shock in front of the flashback).

- The flashback arrestors are build Conform to: EN 730/ISO 5175 and with BAM Certification no.: ZBF/009/12

Safety

For safety reasons we strongly recommend annual testing of the flashback arrestors, and to change flashback arrestors every 5 years. For vessels under OCIMF SIRE and RIGHTSHIP RISQ, replacement of the flashback arrestor is mandatory after 5 years from date of manufacture. Manufacturing date code can be found on the flashback arrestor.