C-Loop and the business of turning waste into value

Article AI-summary approved by the editor:

-

From waste to worth: C-Loop, a Wilhelmsen spin-off, is redefining maritime waste by collecting and recycling high-quality materials like mooring ropes into new products, pioneering a circular economy within shipping.

-

Smart, scalable circularity: With its lean team and Wilhelmsen’s backing, C-Loop’s 'RopeLoop' model offers shipowners a cost-effective, zero-waste solution while generating recurring revenue and ensuring sustainability compliance.

-

Changing habits, not just systems: The main challenge isn’t tech, it’s mindset. C-Loop aims to make reuse more convenient than disposal, helping shift shipping from a throwaway culture to a lifecycle-driven approach.

“The maritime industry generates huge amounts of valuable materials that are simply thrown away when equipment needs replacement,” says C-Loop CEO Tore Strand. “It’s complete madness. These are high-grade materials built to survive the harshest environments. We’re not talking about recycling rubbish – they’re materials that just happen to be at the end of their first life.”

REINVENTING GRANDPA

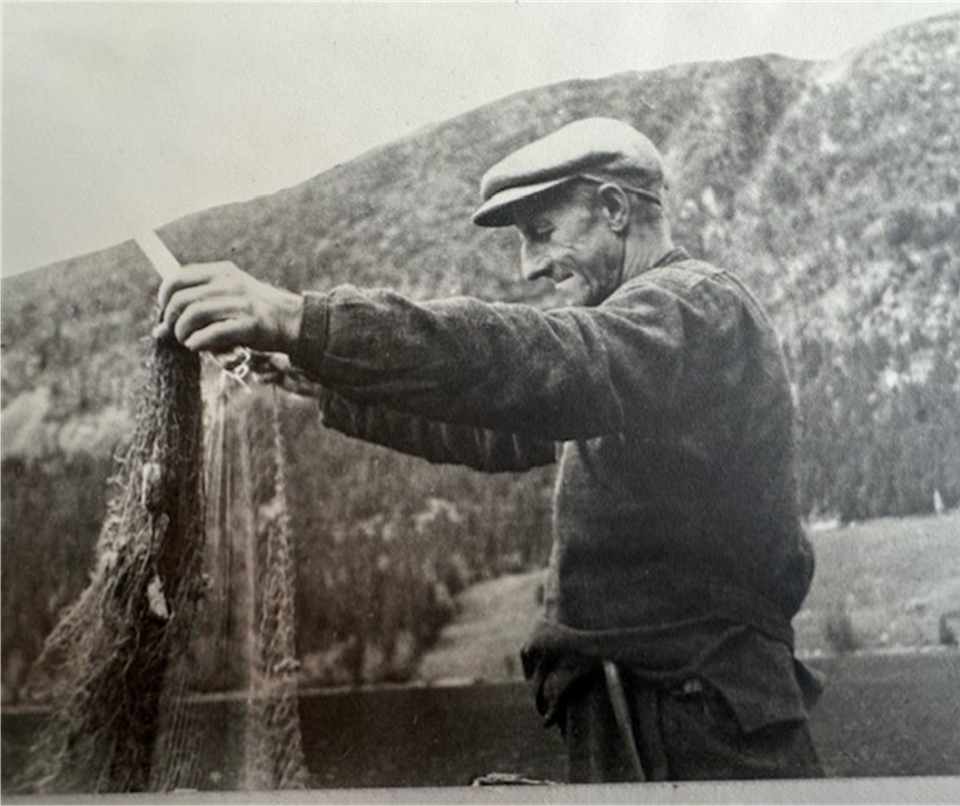

Strand feels like he’s reinventing his grandfather. “When I renovated our family cabin in the mountains, I found fishing nets stuffed into the walls as insulation,” he recalls. “My grandfather did that 70 years ago. We’re just doing the same thing again – reusing what’s already good.”

That image has become his personal metaphor for the whole business. “A hundred years ago, reuse wasn’t ideology, it was instinct. We’ve built an entire economy on forgetting what our grandparents knew,” he says. “Now we’re relearning it with spreadsheets and ESG metrics.”

After three decades in the rope industry – including running one of Norway’s largest rope manufacturers before its acquisition by Wilhelmsen in 2016 – Strand has seen how stubbornly linear shipping can be. “The industry’ default is buy-use-dispose,” he says. “People don’t feel the pain because waste has always been invisible – out of sight, out of mind.”

A NEW KIND OF PROBLEM-SOLVING

C-Loop’s mission is to prove that waste is not an unavoidable cost of doing business but a resource waiting for transformation. It was born out of Wilhelmsen’s recognition that closing the material loop requires a different mindset from traditional shipping operations.

“Making C-Loop a separate company allows us to move at start-up speed while leveraging Wilhelmsen’s network and credibility,” says Strand. “We can test, fail fast and pivot without disrupting Wilhelmsen’s core operations – but still draw on 160 years of maritime experience.”

With a leadership team of two – Strand in Oslo and Captain Vineet Batura heading up the operations and partnerships hub in Singapore – C-Loop runs lean but global. Strand calls it “an extremely small company sitting on a gigantic opportunity”. Smallness is its strength. “We can move quickly, test ideas and learn without bureaucracy – but we still have Wilhelmsen behind us. You couldn’t start something like this in a garage,” he adds. “I get my salary and the freedom to build something that could actually change the system. So, I’m lucky.”

Timing, he says, has been crucial. The convergence of regulatory pressure, ESG priorities and advances in material recovery has created the perfect conditions for change. “Shipowners are increasingly being held accountable for their full lifecycle impact, not just operational emissions,” he explains. “At the same time, material shortages and price volatility make resource recovery not just responsible, but smart business.”

That blend of agility and reach is helping C-Loop start to build the kind of ecosystem circularity depends on. Early partnerships stretch across sectors and geographies – for example, compounders in Sweden supply automotive manufacturers with recycled fibres for seat upholstery, while rope processors in Vietnam spin new fibres for the domestic fishing industry. “We don’t have to own everything,” Strand says. “We just have to make the system work.”

WHAT CIRCULAR REALLY MEANS

For Strand, circularity must be backed by viable business models. “For shipowners, it’s about turning cost centres into value creators,” he says. “Instead of paying disposal fees and managing complex waste regulations, they can generate value from materials they used to throw away. For suppliers, it means shifting from selling products to managing lifecycles – ensuring ropes, ladders and other consumables continue creating value through multiple lives.”

C-Loop’s 'RopeLoop' concept embodies that thinking. Mooring ropes – replaced frequently and made from durable synthetic fibres – are ideal candidates. Under the model, C-Loop provides ropes on a service/rental basis, monitors their condition, retrieves them when due for replacement and recycles them into new ropes, textiles or composite materials.

“The customer gets predictable costs, zero waste disposal and clear sustainability reporting. We get recurring revenue and a steady supply of high-value material,” says Strand. “It’s not about waste management; it’s resource management.”

REGULATIONS CHANGING THE GAME

The EU’s Extended Producer Responsibility (EPR) and Corporate Sustainability Reporting Directive (CSRD) are reshaping how companies handle products from cradle to grave.

“EPR makes producers financially responsible for the entire lifecycle of their products,” Strand explains. “Waste is no longer someone else’s problem – it becomes a direct cost. CSRD adds reporting pressure, while C-Loop provides not just the physical service but the data trail and documentation customers need for compliance.”

When disposal becomes expensive and transparency mandatory, circular business models “start to make pure financial sense".

BREAKING HABITS

What holds the model back isn’t technology – it’s habit. “It’s too easy to just throw things into a rubbish container,” Strand says. “That’s the real enemy.”

Still, momentum is shifting. Wallenius Wilhelmsen and Maersk are now piloting the service, and ports are exploring circular-economy zones where materials can be processed close to where they’re collected. “It's about making reuse the most convenient option,” Strand says.

He jokes that he needs “a couple of beers on a Friday to recover from battling the system". The humour masks frustration, but also resilience – which all social entrepreneurs require. “Someone has to be the first mover,” he says. “If we can prove that circularity works for ropes, it will work for everything else. That's the goal.”

LOGISTICS WITHOUT REINVENTION

One of C-Loop’s strongest assets is its ability to plug into Wilhelmsen Ships Service’s global logistics network rather than build one from scratch. “We integrate rope take-back into existing delivery routes, so the marginal logistics cost is minimal,” Strand explains.

Collected ropes are sent to certified processing partners that document every step of transformation. “Customers receive full chain-of-custody records showing how materials were processed and what they became,” he says. “Transparency builds trust – and meets new reporting standards.”

IMPACT WITH INTEGRITY

Despite the growing attention, Strand remains wary of hype. “I’m terrified of being used for greenwashing,” he says. “A good story is fine, but there has to be real content behind it – measurable savings, verified processes, full transparency.”

That’s why C-Loop invests in life-cycle assessments to document the environmental effect of every loop. “If we move ropes to Vietnam for re-spinning, we calculate that footprint too,” he says. “It has to add up. Otherwise, we’re just moving the problem around.”

He believes circularity must be rooted in integrity – and in business sense. “If it only works as a feel-good story, it will disappear. If it works economically, it will last.”

THE 'INFINITE MINDSET'

Few start-ups begin life with the reach of a global maritime group. “We couldn’t replicate Wilhelmsen’s expertise and operational footprint,” Strand admits. “Their backing gives us instant credibility and access to customers and infrastructure that would take decades to build.”

The alignment goes deeper than logistics. “Wilhelmsen’s 'infinite mindset' is about building businesses for generations, not quarterly returns. C-Loop applies the same principle to materials – keeping them in motion, creating value again and again.”

However, his ultimate measure of success isn’t financial. “It’s when people in shipping can’t imagine throwing away valuable materials because reuse has become automatic – and profitable. That’s when we’ll know we’ve truly looped the maritime industry."

Article by Roddy Craig.