Gas Welding – Acetylene vs Propane

Facts

- The flame temperature when burning Propane in Oxygen is 2800 degree C

- The flame temperature when burning Acetylene in Oxygen is 3100 degree C

Propane (also called LPG—liquefied petroleum gas—or LP gas) is a widely used fuel. It is transported an stored as a very cold liquid, and can cause a “freeze burn” or frostbite if in contact with the skin. The liquid propane is turned into a gas inside a tank or a cylinder. In its natural form, propane is colourless and odourless. To make propane easier to detect in the event of a leak or spill, manufacturers add a chemical compound to give it a distinctive smell.

Welding

Firstly: Propane cannot be used for Gas Welding. When acetylene burns in oxygen, it creates a reducing zone that cleans the steel surface. Propane do not have a reducing zone like acetylene and can hence not be used for Gas Welding.

Brazing

Propane can like acetylene be used for Brazing. For capillary brazing (silver brazing) equal result. For Braze “welding” (thick flowing brazing alloys) acetylene will be an advantage

Cutting

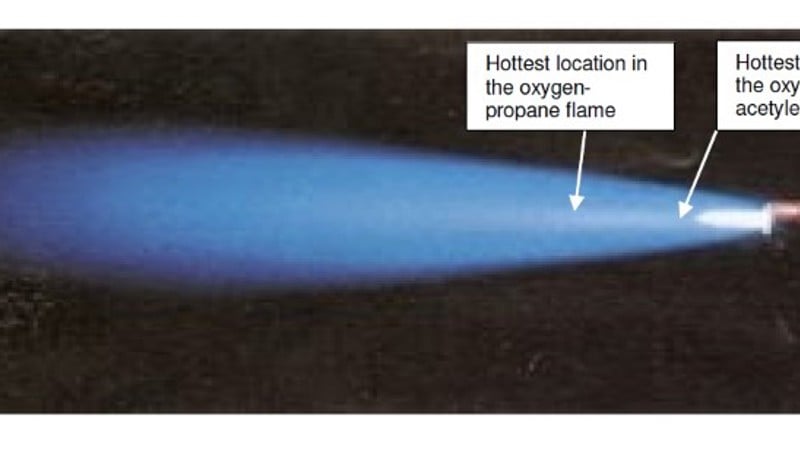

Propane can like acetylene be used for cutting. If you cut with acetylene, you normally put the tip of the inner flame cone on the metal (1mm from the plate surface). If you do the same with propane, you will be waiting for a long time. If you raise the torch so that the outer flame cone is used the preheat process is started faster. Propane releases only a small proportion of heat in the inner flame cone (less than 10%), so most of the heat in the flame is located in the outer cone. Acetylene releases almost 40% of its heat in the inner flame cone.

Therefore, acetylene is better for cutting than propane. While temperature wise acetylene is hotter than propane the fact is that people are using propane for cutting incorrectly. The mistake they make is that they are cutting with propane as they would cut with acetylene. Where the heat is in the propane preheat flame is not where it is with acetylene. In short, it takes a different technique to use propane for cutting and in general, acetylene preheats faster. The Ship breaking/ ship demolition yards and scrapyards are often using propane for cutting because cutting quality is of no concern.

Heating

…is a different matter. To say propane gives off less heat it is not correct (plain wrong actually). Acetylene is hotter but gives off less heat. The majority of preheating is done with Oxygen / Propane. This is a fact. The available heat from propane is higher.

Equipment

Cutting require different cutting attachments and cutting nozzles

Economy

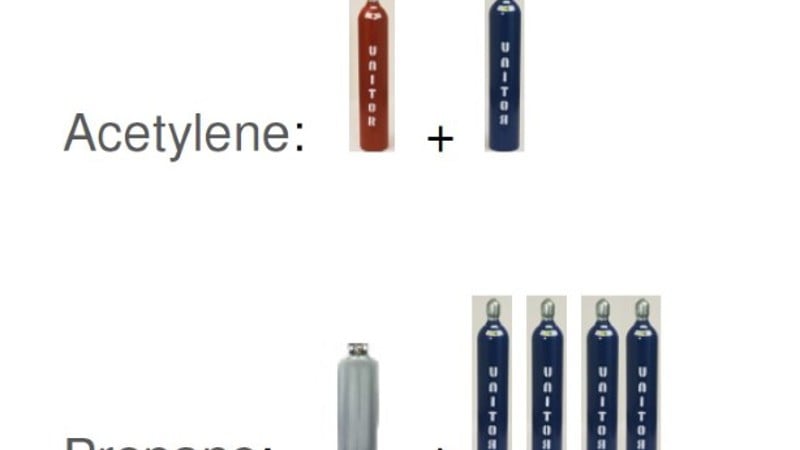

Propane has greater stoichiometric oxygen requirements than acetylene. For the maximum flame temperature in oxygen, the ratio of the volume of oxygen to fuel gas are 1,2 to 1 for acetylene and 4.3 to 1 for propane. So, there is far more oxygen being consumed when using Propane. Despite Propane being less expensive than acetylene, this is counteracted by the higher oxygen consumption.

Safety

The most important drawback using propane on-board are never the less the safety aspect.

Acetylene’s specific gravity is 0,9 so it is lighter than air (1). If gas leaks out it will raise. The Specific Gravity of Propane is 1,6 and heavier than air (the same for other hydrocarbon gases like butane and MAPP* (modified propane gas)). Any propane leak in an enclosed area will sink and become concentrated at the deck level, accumulate and sometime avoid detection.

For propane to burn effectively, the oxygen-to-gas mixture must be within a certain range. For ideal conditions, there should be four parts propane to 96 parts oxygen. When the gas burns outside of these parameters, the result is incomplete combustion; this produces excessive carbon monoxide. This can be very dangerous if the space does not have proper ventilation. Onboard a ship one sometime work in enclosed areas like ballast tanks and double bottoms. Carbon monoxide poisoning can result in death, as the toxic gas replaces the oxygen in the bloodstream.

*"MAPP gas" is a trademarked name, belonging to The Linde Group. The name comes from the original chemical composition, methylacetylene-propadiene propane. "MAPP gas"

Download Technical update - Gas Welding - Acetylene vs propane