Due to VLSFOs having three times the level of saturates (paraffins) and half the aromatic content compared to HFOs (High Sulphur Fuel Oil), they have a higher susceptibility to wax precipitation.

The quality of VLSFOs is expected to continue fluctuating as the composition of fuels can come from different blenders or refiners, leading to varying fuel properties. This entails possible wax formation in fuel tanks due to high paraffinic content in VLSFOs and this waxing issue is further exacerbated in colder climates.

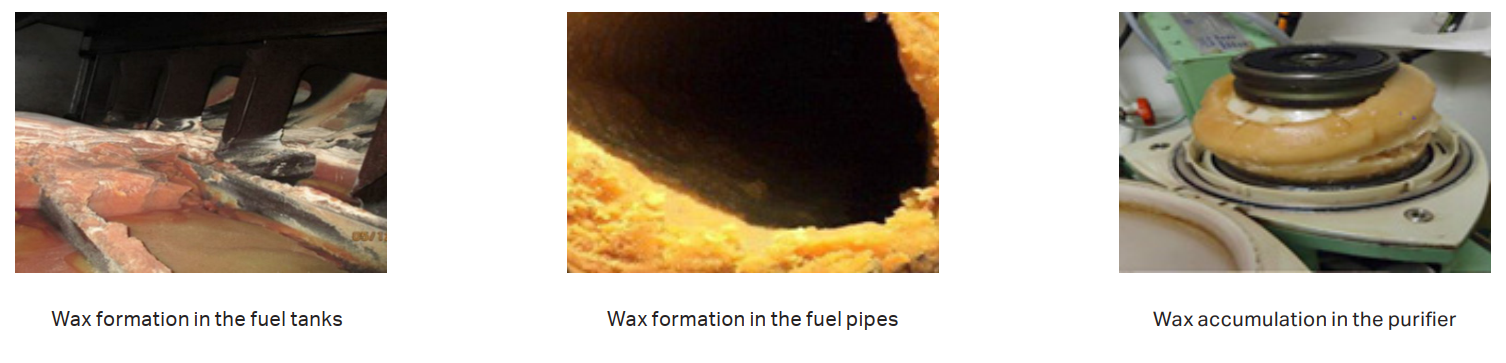

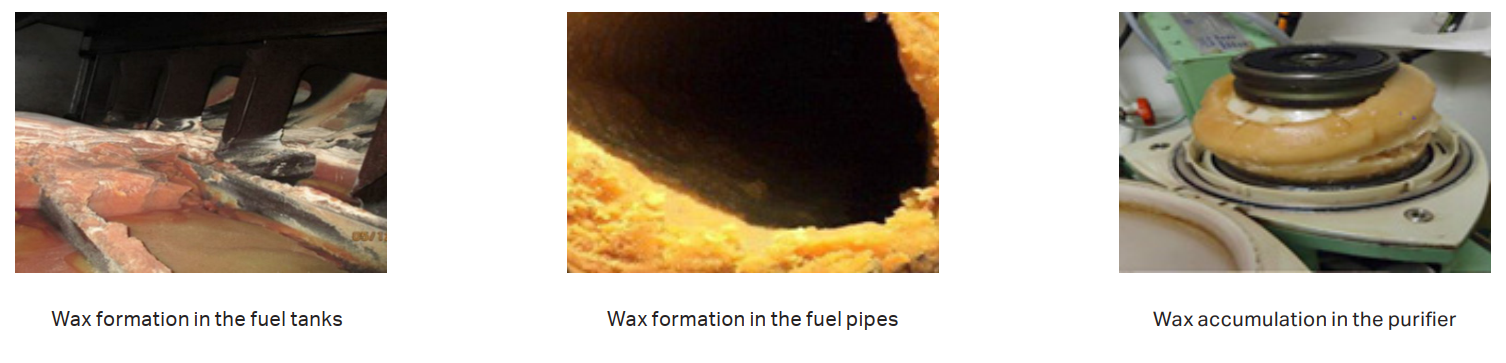

These wax formations are essentially sludge masses which accumulate in fuel tanks – potentially blocking and damaging fuel filters; choking fuel pipes and fuel tanks. If the vessel experiences the phenomenon below, the cost incurred from the clean-up can be immense, on top of irreversible damages.

This issue is discussed in an

article in the World Bunkering magazine where our Head of Product Management - Energy, Jonas Ostlund, shed some light on the technicality behind these issues, and reiterated the importance of fuel treatment to resolve these waxing issues.

When asked about his views on fuel issues relating to stability, compatibility, sludging, waxing and poor cold flow properties, Jonas highlighted that all these issues are already happening since the vessels transitioned to VLSFO: "Stability seems to have become a more serious problem with VLSFOs in conjunction with the wax and cold flow properties... We have also seen a drop in viscosity since the introduction of VLSFOs and on average VLSFO contains three times as much saturates compared to high sulphur fuels and have a higher pour point that can lead to operational problems."

At Wilhelmsen Ships Service, we have the full set of solutions to address these concerns through our Test & Treat program, which includes treatment chemicals that reduce solid wax build up in marine fuel storage, improving pumpability, while reducing onboard losses during transfer and helping to minimize the impact on vessel heating capacity. We also have test kits to monitor engine wear during operation so potential issues can be identified and corrected.

Find out more about our Unitor™ FuelPower™ PPD VLSFO here

Find out more about our Unitor™ DieselPower CFPP here