Why is corrosion in cooling‑water systems a hidden profit killer?

威尔森观察

|

Han Ding Hou, Global Product Marketing Manager - Water Solutions

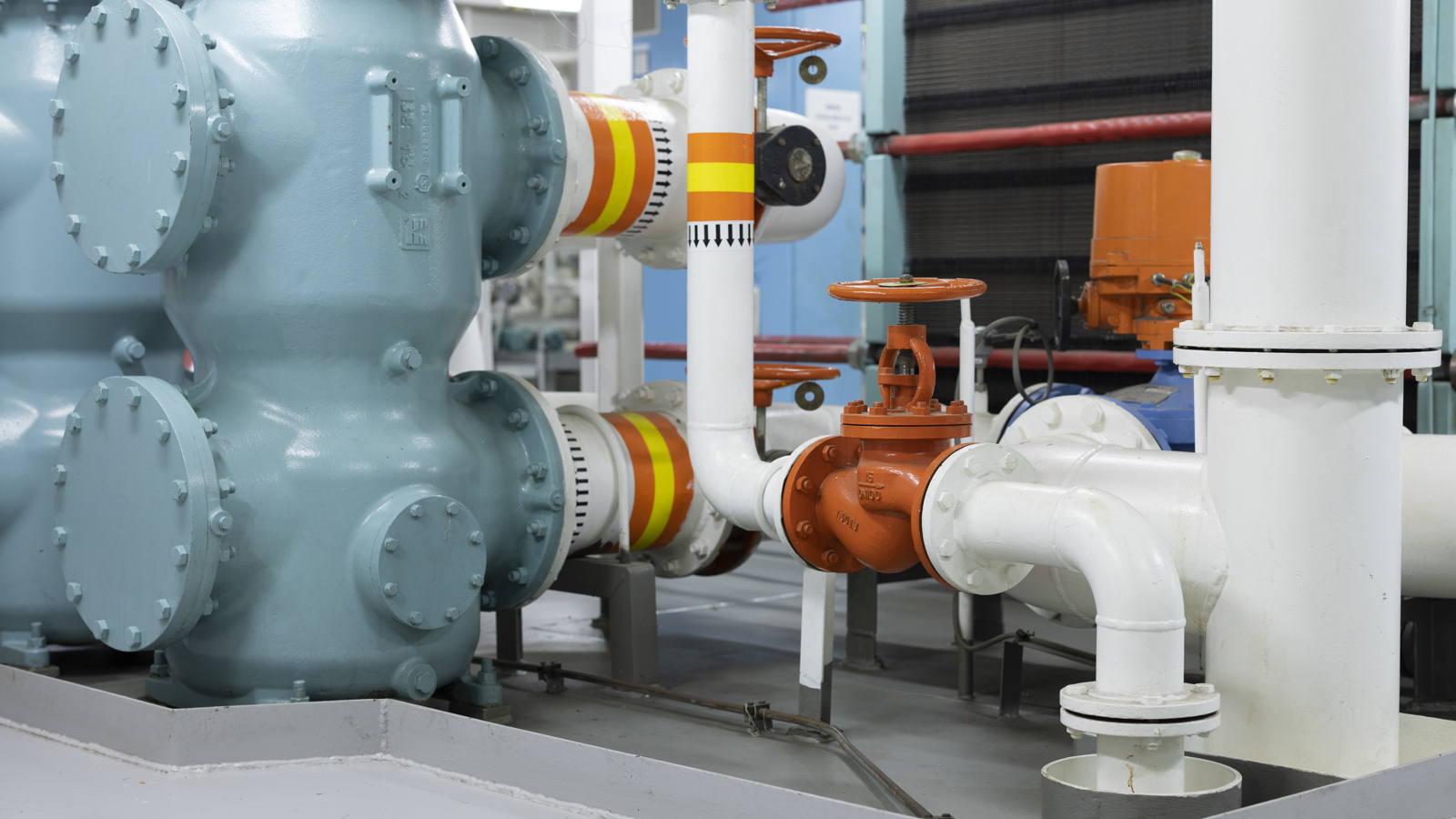

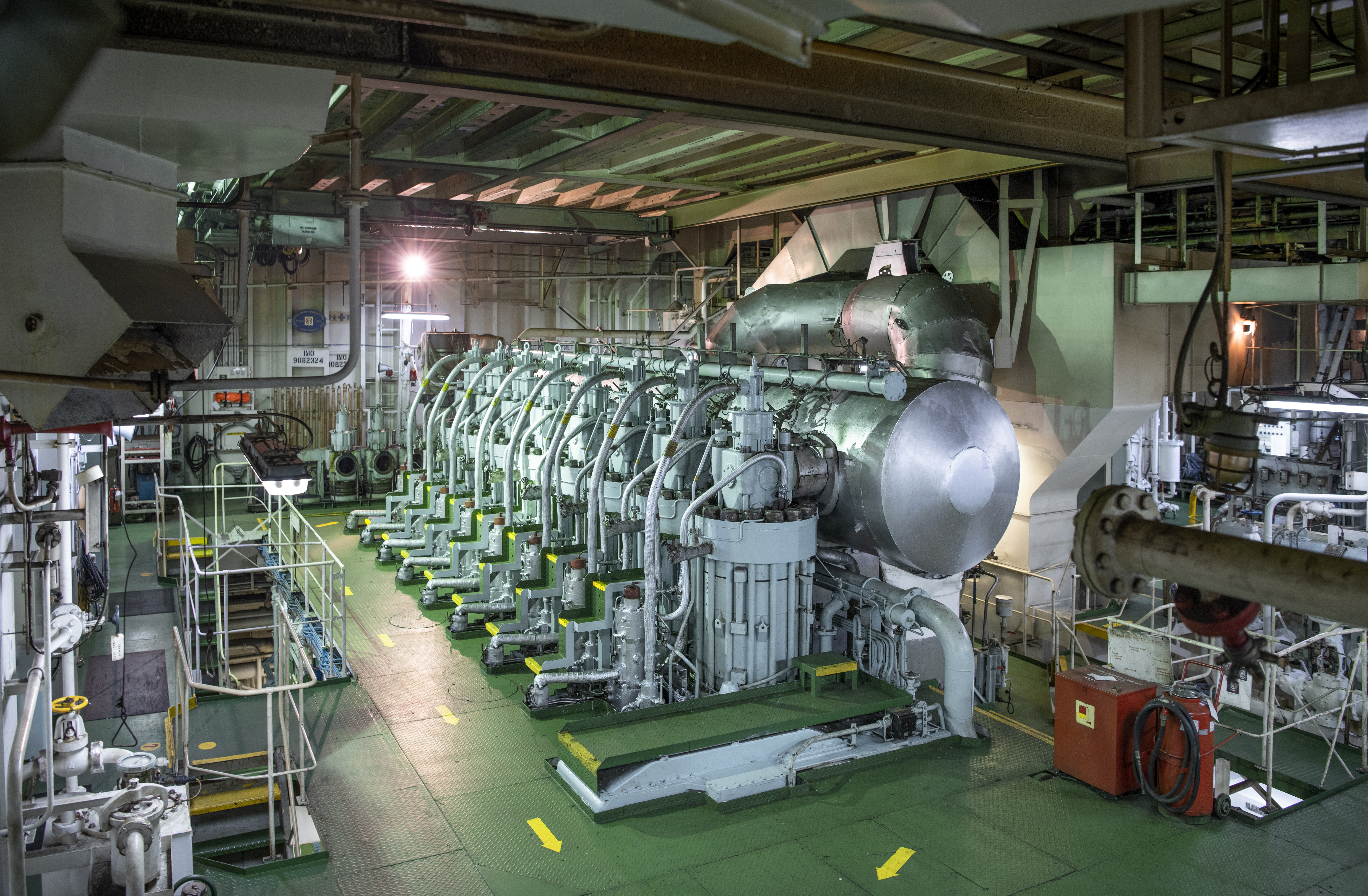

Nothing stops a voyage faster than an overheated main engine. Cooling-water system might have a bigger part to play in engine overheating. Onboard cooling-water systems carry every-present risk of water contamination and corrosion. Non distilled or freshwater contains high concentration of minerals and other contaminants, using untreated water can lead to corrosion if not addressed in timely manner with a combined chemical approach. In a survey, 68 % of chief and second engineers said water-system upsets were among their top three unplanned maintenance headaches, outranking even lube-oil problems.(Ref. dieselduck.info)

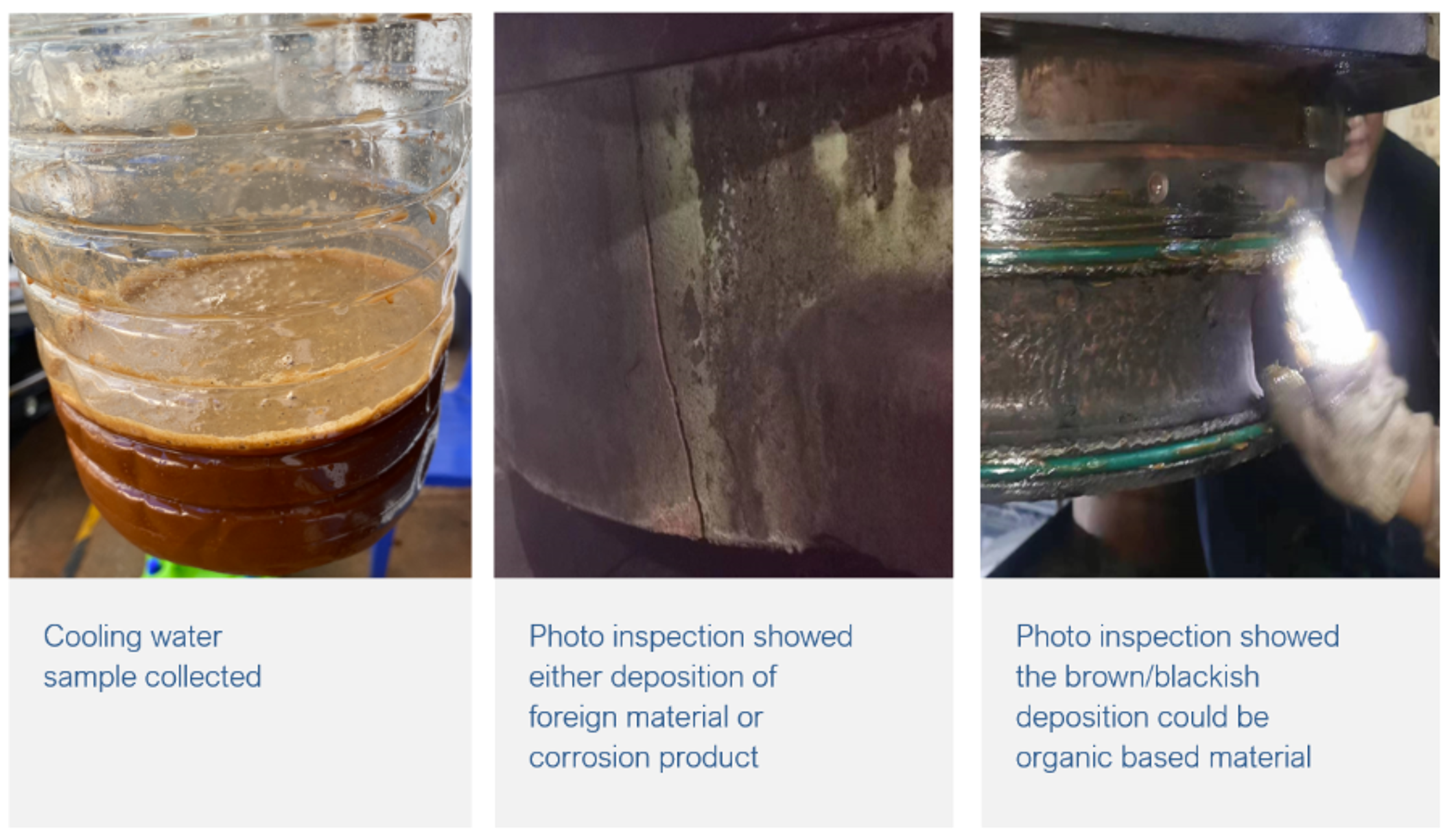

What the problem looks like

|

System |

Visible symptom |

Hidden cost |

|

Cooling-water circuits |

Corrosion: Red brownish water, Iron sludge accumulation at strainer, scaling and deposition at heat exchangers, biofouling induced slimy/foul smelled, corrosion inhibitor decreasing other than water loss |

• Up to 15 % fuel penalty from reduced heat-transfer efficiency (Ref. myjobquote.co.uk) |

Sludge forming on surface of condenser

Why Does It Keep Happening?

- Low-quality bunkered water – Shore-side municipal water can arrive with bacteria counts >10 000 CFU/ml or chlorides >600 ppm. (Ref. marinevac.com)

- Incorrect management of water treatment program control – Lack of awareness, not adhering to recommended water quality guidelines, no dedicated water quality performance system such as waterproof

- Micro-biologically Influenced Corrosion (MIC) – Biofilms undercut the protective magnetite layer in pipelines in as little as 14 days at 35 °C.

- Crew workload & turnover – In our survey, 72 % of respondents link delays directly to knowledge or skill gaps on board.

Operational & Financial Fallout

- Direct repair cost – A single 50 m section of 65 mm potable line costs USD 2 000–3 000 in parts and labour; full replacement can exceed USD 400 k on medium-age cruise ships.

- Off-hire / speed loss – Cooling-water fouling can push main-engine jacket temperature up 3–5 °C, forcing an emergency slow-down costing ≈USD 50 k/day in charter revenue. (Ref. standard-club.com)

- Operational stress – Unplanned maintenance activities resulted avoidable stress and excessive workload.

How Wilhelmsen Ships Service keeps your water system flowing seamlessly

|

Pillar |

What we deliver |

Proof-point |

|

Global availability |

Water-treatment chemicals available at over 2,200 port destinations |

98 % OTIF deliveries in 2023 despite supply-chain shocks |

|

Expert service |

Over 100 subject-matter experts; 24/7 remote lab; onboard audits |

Average 3 h response time to water alerts |

|

Proven solutions |

Nalfleet™ range (Rcoor NB, Nalfleet 2000, Cooltreat Al, Cooltreat ELC); test kits (Spectrapark 309) |

Majority of treatment products recommended by major engine OEMs. |

|

Digital tools |

WaterProof app logs test data, auto-calculates dosing and archives reports for PSC |

Over 12 000 monthly test entries; zero data-loss incidents |

Step-by-step programme

- Treatment program selection and design – Dedicated selection criteria based on ship onboard cooling system, inhibitor type leading to tailored made engine cooling water recommendations, etc.

- Control set-up – Customized treatment program, control guideline, monitoring are set up at Waterproof for dedicated cooling water system performance monitoring.

- Continuous monitoring – WaterProof sends weekly KPIs; anomalies trigger remote advice within 2 h.

- Performance review – Quarterly cooling water quality health report benchmarks and usage rate vs fleet peers.

Tangible Gains for Operators

- Up to 20 % extension in cooler service intervals

- Crew satisfaction scores up 12 % due to palatable water supply (major cruise line feedback 2024)

Ready to Make Rust a Thing of the Past?

Cooling water health and performance may be the lifeblood of your vessel but unmanaged it quickly becomes nightmare. With Wilhelmsen’s global reach, proven chemistry and unrivalled expertise, you can turn two of the most overlooked systems into silent productivity drivers.

Get in touch with our experts

Talk to our water experts today and discover how we can support your operational challenges for your vessel's cooling-water systems.

Han Ding Hou

Global Product Marketing Manager

With over 18 years of expertise in water treatment, Hand Ding Hou brings deep technical and strategic knowledge across diverse applications, including boiler water, engine and cooling water, ballast water, potable water, and wastewater systems. His career spans global markets, where he has led product innovation, lifecycle management, and application development to optimize performance and sustainability. Han is recognized for driving solutions that meet stringent regulatory standards while delivering operational efficiency for industrial and marine sectors.