Preventing Cross-Contamination Between Cargoes

Clean cargo holds are the backbone of efficient, compliant, and profitable shipping operations. Yet, the transition between different cargoes-especially from dirty to sensitive cargoes presents a host of challenges that, if not managed proactively, can lead to costly contamination, regulatory breaches, and operational delays.

Regulatory compliance is a critical driver in the cargo hold cleaning process. International maritime regulations, such as MARPOL Annex V and IMO guidelines, set stringent standards for the cleaning and maintenance of cargo holds to prevent the discharge of harmful residues and unapproved cleaning agents into the marine environment. These regulations are not merely procedural requirements, they are essential safeguards for environmental protection and the industry’s reputation.

To meet these standards, the Wilhelmsen cleaning process is designed to ensure that all Unitor™ and Navadan™ cleaning agents are fully MARPOL-compliant and specifically engineered for safe use in marine environments.

Below, we break down the key types of challenges faced in cargo hold cleaning and outline how Wilhelmsen’s solutions help you overcome them.

1. Residual cargo deposits

After unloading bulk cargoes such as coal, petcoke, or sulphur, fine residues often remain embedded in the hold. These remnants can contaminate subsequent sensitive cargoes like grain, cement, or fertilizers, leading to quality disputes, rejected shipments, and financial losses.

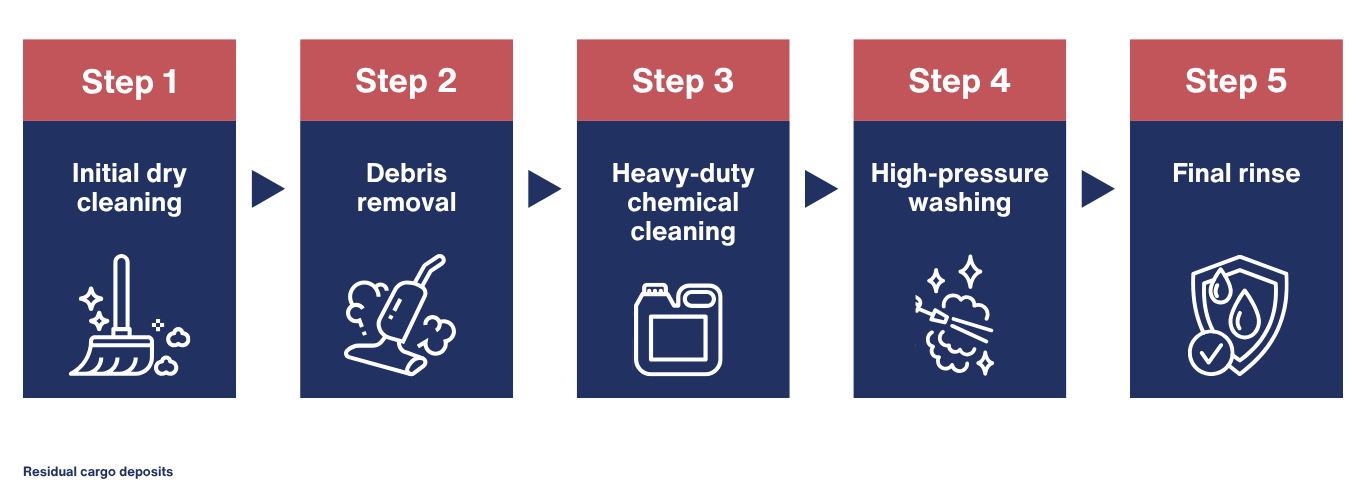

Solution: it's critical to begin cleaning immediately after discharge with a thorough dry-cleaning phase, followed by a targeted chemical and high-pressure wash.

- Initial dry cleaning: as soon as a cargo hold becomes empty, the crew should begin removing all major cargo residues. Use tools such as steel scrapers, corner brooms, and vikan brushes to scrape and sweep down residues from frames, ladders, and other structural elements. Sweep the tank top thoroughly at least twice to collect and discharge as much residue as possible to shore.

- Heavy-duty cleaning: apply Unitor CargoClean HD, a powerful alkaline cleaner, to break down stubborn residues.

- High-pressure washing: to achieve optimal cleaning performance, a foaming application is essential. The foam creates a blanket of millions of tiny bubbles that physically lift dirt and residue from the surface. This mechanical action, combined with the chemical's combined with the proprietary combination of selected surfactants in the chemical, results in a more thorough and efficient clean. With the Navadan Ultimate Kit (to be used with Unitor Cargoclean HD), thoroughly wash down all surfaces, ensuring the complete removal of embedded particles.

- Final rinse: perform a final washdown with fresh water using Navadan Tornado Kit. If seawater is used for washdown, Navadan Maxi Jet should be considered. Use hot water if possible and check the results.

By following this systematic process, holds are left residue-free, significantly reducing the risk of cross-contamination, and ensuring compliance with stringent cargo requirements.

2. Chemical residues and staining

Improper cleaning or rinsing can leave behind chemical residues, stains, or lingering odours, especially after transporting oily or staining cargoes (e.g., petcoke, coal). These residues can taint the next cargo and may even cause paint blistering or odour transfer.

Solution: specialized chemical treatments and protective coatings

- Targeted chemical application: after the initial cleaning, apply either Unitor CargoClean HD or Navadan CleanHold (2-5% solution) to treat surfaces and prevent the re-deposition of contaminants. Repeat the cleaning process if necessary to ensure all stubborn stains are eliminated.

- Heavy-duty performance: If stubborn or sticky stains remain, use Navachlor 812, a specialized cleaner designed to remove adhesive oily stains. Navachlor 812 should only be applied when the cargo holds have dried up properly, after the completion of cleaning with Cargoclean HD or Navadan CleanHold.

- Protective barrier: to prevent future contamination and simplify cleaning, apply a protective coating before loading the next cargo. Protective barrier coatings such as Navadan BarrierHold or Unitor Slip Coat can prevent difficult dry cargoes such as coal, coke, petcoke from sticking to cargo hold surfaces. This film provides a barrier between the cargo and the cargo hold surfaces making the cleaning operation after unloading quicker and easier securing an optimal cleaning result.

Cargo holds are left free from stains and sensitive cargoes such as grains or foodstuffs are protected from chemical tainting. The application of a protective barrier not only safeguards the current cargo but also ensures a more efficient turnaround for the next voyage.

3. Rust, Paint Flaking, and Moisture

Rust, scale, flaking paint, and trapped moisture in cargo holds can contaminate new cargoes and cause further deterioration of the hold’s protective coatings.

Solution: The key to preventing rust and flaking is thorough preparation. Protective coatings will not adhere properly if there is any loose rust or paint.

- Rust removal: use high-pressure cleaning (Unitor™ HPCE Dynamis 500+) and manual scraping with brushes or scrapers to remove loose rust and paint.

- Drying: deploy mechanical ventilation and mopping to ensure holds are completely dry before loading, preventing cargo spoilage.

- Protective coatings: with a clean and dry surface, apply Navadan BarrierHold or Unitor™ Slip-Coat to prevent difficult dry cargoes from sticking to cargo hold surfaces. This crucial preventive step maintains the structural integrity of the hold.

Holds remain structurally sound, and cargoes are protected from contamination by rust or paint flakes. Proper preparation ensures our protective coatings work effectively, extending the life of the hold's surfaces.

By addressing each type of challenge with a targeted combination of Unitor equipment and Navadan chemicals, Wilhelmsen delivers a proactive, end-to-end solution for cargo hold cleaning. This integrated approach not only prevents cross-contamination but also streamlines operations, ensures compliance, and protects both cargo and vessel value.

Ready to optimize your cargo hold cleaning? Contact our specialist team for tailored advice, or follow Wilhelmsen on LinkedIn for more best practices.

Featured Offers

-

How to reduce safety risk with our innovative cargo hold cleaning solutions

Efficient cargo hold cleaning is essential for ensuring vessel readiness and operational efficiency. Traditional manual cleaning methods have relied on crew members scaling ladders, manually scrubbing hold walls, and removing hardened residues, which together pose various hazards to health and wellbeing.

-

-

货舱清洗,做得更好

船东和船舶经营人要求更高效的压力越来越大。船舶装载不同货物时的洗舱至关重要,现在,洗舱比以往任何时候都受到更严格的管制。不符合规定的代价很高,会造成船舶在港口被滞留,直至符合规定。