Refrigerant Leak Monitor

Unitor fixed leak detector is the natural first choice when you need an economical solution to provide round-the-clock leak detection and monitoring.

Sensors detect ambient refrigerants to levels as low as 100 ppm. (Standard setting 500 & 1000 ppm.)

- Increase crew safety

- Reduces environmental impact

- Help reduce refrigerant consumption

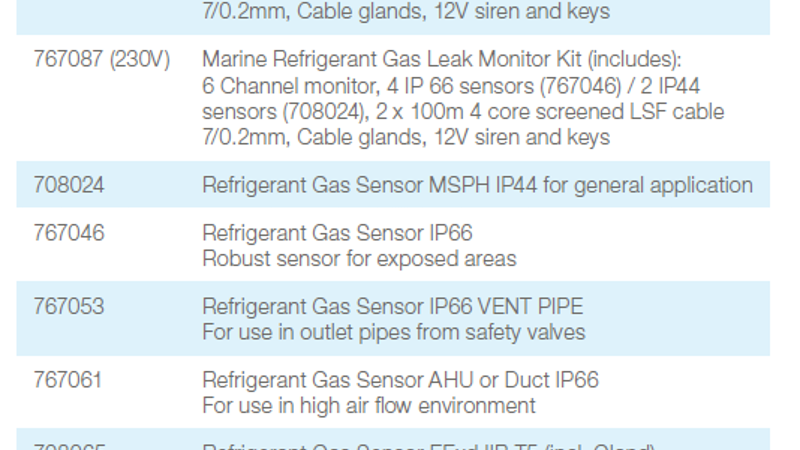

Optional sensors

- Designed to minimise false alarms from background gases

- Sensor PCB design with incorporated test points

- Simple annual maintenance

- IP66 sensors for high humidity, wash down areas, and fast response

Benefits

- Crew Safety: Safeguards crew members from long-term exposure to high levels of refrigerant gas.

- Cost Saving: Helps reduce costs due to accidental loss of refrigerants from unmonitored leaks

- Environmentally Sound Solution: Reduces the risks of global warming and damaging the Ozone layer by instantaneous warning of leaks

- Class Compliant: The leak detection system is compliant with classification societies requirements (LRS, DNV, ABS and more)

Extra Advantages

- Relatively easy to install, requires no special preparations

- Economical solution

- Robust, with no moving parts

- Low maintenance requirements

- Can be connected to existing engine room alarm systems

- Single phase 230V 50/60 Hz (110V on request)

- Can be recalibrated on board by ships crew

Features

- No moving parts

- Inexpensive and long-lasting semi-conductor technology

- Detects a range of gases including all CFC, HCFC & HFC refrigerants.

- Can detect multiple refrigerants simultaneously

- Available as 4 or 6 channel monitor kits (one sensor per channel)

- 2 level alarm system

- Low level alarm resets automatically

- High level alarm needs to be manually reset

The greatest environmental impact from an AC system over its lifetime arises from energy consumption. A leaking system is less efficient and a 10% refrigerant loss increases energy consumption by up to 20%.