Case study: how pre-combustion treatment prevented a $75K in fuel loss

Customer background: A customer bulk carrier fleet had encountered an unexpected and severe purifier blockage for one of their deep-sea vessels. In August 2025, the vessel bunkered 893 tons of VLSFO in Panama, with a viscosity of 109.9 mm²/s at 50°C.

Within 2 month of sailing, it was discovered that approximately 150 tons of fuel in one tank had become extremely unstable, leading to rapid sludging, purifier shutdowns within minutes, and growing operational issues. A dedicated Wilhelmsen Ships Service Technical Sales & Business Development Manager (TSBDM) was contacted on technical consultancy for an emergency solution to recover the remaining fuel safely without compromising the engine condition.

The challenge: severe sludging in the fuel purifier threatening vessel operations

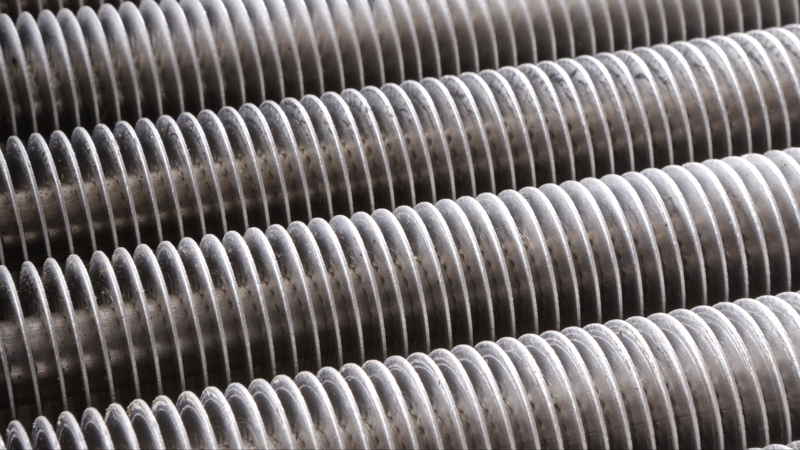

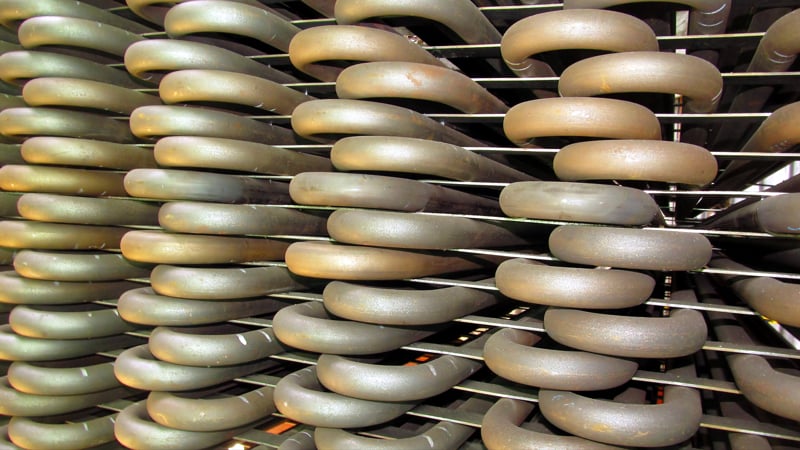

Attempts to run both purifiers resulted in immediate blockage. The sludge discharge system, bowl, drainage chamber, and even water channels became packed with heavy deposits, pushing the engine team into repeated dismantling cycles.

Operational risks were escalating:

Operational risks were escalating:

- Unpredictable fuel handling with longer fuel storage onboard (over 3 months)

- Increased workload and safety concerns for engineering staff with extremely shortened de-sludging cycle (several minutes)

- Potential loss of 150 tons of fuel (up to USD $75,000)

- Threatened propulsion margins for the upcoming voyage (delayed voyage)

Wilhelmsen’s response: a structured fuel expert approach

The customer’s TSBDM was a Fuel Expert who upon assessing the situation, recommended a controlled treatment program using Fuelpower Conditioner.

The goal was clear, stabilize the problematic fuel and restore purifier operability without imposing excessive operational burden.

Impactful outcome: restored stability and secured operational safety

Within the first treatment cycle by dosing Fuelpower Conditioner, purifier runtime extended dramatically from several minutes to multiple hours of continuous operation before any new blockage occurred. As treatment continued and dosage was optimized, the vessel experienced further improvements:

- Cleaner sludge discharge pathways, with deposits gradually decreasing

- Higher feed rate capability, eventually increased to 0.6 m³/h as normal vessel operational feed rate

- Significantly reduced manual intervention, enabling manageable purifier cycles even under heavy fuel load

Consequently, the vessel successfully consumed all 150 tons of previously unmanageable fuel, avoiding waste, restoring confidence in the machinery, and ensuring safe margins to reach the next bunkering port.

The Chief Engineer formally documented the experience and sign-off as verified proof of performance by highlighting:

Operational efficiency restored: Fuelpower Conditioner enabled purifiers to run multiple hours instead of minutes, transforming the working rhythm of the engine room team and reducing the need for constant dismantling.

Fuel quality stabilized: the treatment helped disperse problematic asphaltenes and stabilize the VLSFO, showing how chemical conditioning can recover borderline fuels and extend their usability.

Cost & fuel waste avoidance: by enabling the vessel to safely burn all remaining fuel, the operation avoided the loss of 150 tons of bunkers with a significant cost saving up to $75,000.

Increased voyage confidence: maintaining propulsion margins ensured the vessel could reach the next bunkering port without compromising schedule or safety.

This customer case study demonstrates the value of a structured, analytical approach with WSS dedicated TSBDM team to modern fuel quality challenges. As today’s VLSFO blends continue to vary in stability and compatibility, ship operators increasingly require:

- Improved operational efficiency to reduce TCO (Total Cost Optimization) cost

- Safeguard vessel operation and reliability

- Holistic approach for fuel quality management with clear diagnostic practices

By combining on board operational discipline with the right chemical treatment and technical guidance, fuel management intervention can quickly turn a high‑risk situation into a controlled, efficient with a successful outcome protecting both operational integrity and total cost of ownership.

If you’d like to discuss how WSS fuel oil treatment and WSS Fuel Expert can support your fleet’s fuel management challenges for asset protection, please contact your local Wilhelmsen representative.

特色供应

-

Fuelpower Soot Remover Liquid Plus

Newly formulated Unitor™ FuelPower Soot Remover Liquid Plus increases the cleaning/maintenance interval for your exhaust gas economizer/boiler from every 3 months to 12–15 months.

-

Stay Ahead of Cold Weather Challenges

Cold temperatures or climate pose a clear challenge of waxing of your onboard distillate fuels, thus leading to blocked fuel filters / pipelines / equipment or wax settling in fuel in tanks even at temperatures as high as 15°C.

Articles you might be interested in

-

How to choose the right fuel and lube oil test kit for your vessel

This guide is intended to support chief engineers and technical superintendents in selecting onboard test kits that align with vessel size, engine configuration, fuel strategy, and operating profile.

-

Fuel Treatment: Efficiency gains more than just hot air

Systematic fuel treatment can unlock significant operational and financial gains - nowhere during the life cycle of fuel is this more evident than at its end, in the exhaust gas boiler.

威尔森观察 |

Jonas Östlund, Head of Product Management - Energy Solutions -

Embrace fuel diversity for the future

Post IMO 2020, the fuel challenges remain unchanged while being more complicated when Very Low Sulphur Fuel Oil (VLSFO) was implemented in 2020 to be compliant with IMO 2020 regulation. The fuel diversity in the market including residual fuel type (HSFO/VLSFO/ULSFO), distillate fuel type (LSMGO/Diesel), Bio-blends (Bio-VLSFO/HFO, Bio-LSMGO), etc. Invite new challenges and risks.

威尔森观察 |

Alex Qiang, Head of Product Management - Energy Solutions -

Managing fuel quality issues and meeting regulatory requirements

For shipowners and operators, maintaining fuel quality at a time of tightening regulation requires a clear understanding of the challenges

威尔森观察 |

Jonas Östlund, Head of Product Management - Energy Solutions