How to choose the right fuel and lube oil test kit for your vessel

Unplanned downtime and major engine repairs can result in significant daily costs, particularly for larger vessels. One of the most effective ways to reduce this exposure is through proactive onboard testing. When the appropriate fuel and lubricating oil test kits are applied consistently, contamination, incompatibility, and wear-related risks can be identified early, allowing operators to control maintenance costs while protecting critical assets.

Start by Understanding Your Testing Needs

Effective onboard testing begins with a clear understanding of the operational and technical risks each vessel faces. Different engine designs, fuel types, and trading patterns naturally demand different testing priorities. Beyond normal steady-state operation, additional attention should be given to known stress factors such as frequent load changes, slow steaming, extended fuel storage, or operations in regions with inconsistent bunker quality.

By mapping these risks upfront, testing effort can be focused where it delivers the greatest operational and financial value.

Key Fuel Oil Risk Areas

Fuel oil quality and handling have a direct and immediate impact on engine reliability, separator performance, and maintenance intervals.

The most common fuel-related risk areas include:

- Water and salt contamination

- Catalyst fines (aluminium and silicon from refining)

- Fuel instability and sludge formation

- Microbial growth

- Density and viscosity deviations after bunkering

If left unmanaged, these issues can impair combustion efficiency, overload fuel treatment systems, and accelerate wear across the entire fuel system.

Key Lubricating Oil Risk Areas

Lubricating oil condition monitoring complements fuel testing by controlling wear, cleanliness, and corrosion within engines and auxiliary equipment.

Typical lube oil concerns include:

- Total Base Number (TBN) depletion leading to corrosive wear

- Ferrous debris indicating mechanical damage

- Insoluble or soot accumulation

- Viscosity changes

- Water ingress

Regular trending of these parameters enables early corrective action and supports optimized oil drain intervals, reducing reliance on reactive oil changes or unplanned interventions.

Align Testing with Vessel Operations

Once fuel and lubricating oil risks are defined, testing priorities should be aligned with how the vessel actually operates rather than with vessel type alone. For example, vessels burning variable or blended fuels generally require greater emphasis on compatibility and stability testing to prevent sludge formation and separator overload. Slow-speed engines operating on heavy fuels benefit from closer monitoring of catalytic fines and viscosity due to the cumulative impact of abrasive wear on liners and injection equipment. In contrast, medium- and high-speed engines tend to focus more on TBN control, oil cleanliness, and viscosity stability to maintain lubrication integrity, performance consistency, and emissions compliance.

This operational alignment ensures that testing resources are applied to the parameters that matter most for each vessel.

Why This Matters

Most high-severity engine damage is preventable. Industry insurance and loss-prevention studies consistently identify lube oil failures, delayed or incorrect maintenance, and poor fuel management as leading causes of major engine claims. Average main-engine damage incidents frequently reach several hundred thousand dollars per case.

Downtime often dominates the total cost. Unplanned off-hire commonly ranges from US$20,000 to US$50,000 per day, with emergency towing, port deviation, and recovery costs adding further exposure. As a result, even moderate mechanical issues can quickly escalate into six-figure events.

Engine manufacturers reinforce this risk profile through service guidance that emphasizes routine performance evaluation, cylinder condition monitoring, and cleanliness control, areas directly supported by onboard fuel, oil, and wear testing.

How Key WSS Test Kits Address These Risks

Integrating selected WSS test kits into routine onboard checks allows crews to directly connect measured parameters with the risk areas outlined above:

| Focus area | WSS test kit | How the kit supports risk control | Estimated impact if neglected |

| Fuel compatibility and stability | UNITOR Compatibility Test Kit (773153) | Identifies unstable blends early, preventing sludge formation and separator overload | US$50k–150k (fuel system cleaning, separator/injector wear, downtime) |

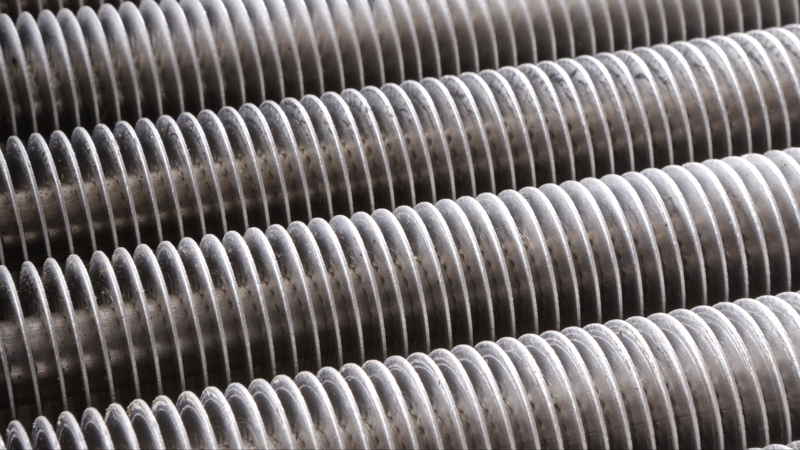

| Fuel quality and catalyst fines | UNITOR Catalytic Fines Test Kit (735748) | Verifies purifier effectiveness and protects injectors and liners from abrasive wear | US$100k–500k+ (injectors, pumps, liner wear) |

| Lubrication integrity (acid neutralization) | UNITOR TBN Test Kit (673150) | Supports condition-based oil changes and prevents corrosive damage | US$150k–600k+; severe cases up to US$2M |

| Mechanical wear trending | UNITOR Ferrous Wear Test Kit (735754) | Detects abnormal wear debris early in rings, liners, and bearings | US$100k–500k+ (expanded overhaul scope) |

From Reactive Fixes to Proactive Control

A practical starting point is to review the previous 12 months of laboratory reports, off-hire incidents, and major component findings. This helps identify recurring issues and gaps in onboard testing coverage. Test parameters should then be prioritized where problems have historically occurred or where the operational and financial consequences of failure are highest.

By selecting the right combination of fuel and lubricating oil test kits, operators can move from reactive repairs toward planned, data-driven maintenance—resulting in improved reliability, reduced downtime, and more predictable operating costs.

Download the selection guide below to determine which test kits are most appropriate for your vessel size, engine types, and operating profile.

特色供应

-

Fuelpower Soot Remover Liquid Plus

Newly formulated Unitor™ FuelPower Soot Remover Liquid Plus increases the cleaning/maintenance interval for your exhaust gas economizer/boiler from every 3 months to 12–15 months.

-

Stay Ahead of Cold Weather Challenges

Cold temperatures or climate pose a clear challenge of waxing of your onboard distillate fuels, thus leading to blocked fuel filters / pipelines / equipment or wax settling in fuel in tanks even at temperatures as high as 15°C.