Raising standards of safety and efficiency through high pressure cleaning

Cleanliness onboard a vessel is a core requirement for safe operations, compliance with international standards, and the overall wellbeing of the crew. Yet, shipboard cleaning remains one of the most demanding and resource-intensive activities carried out at sea. From hardened grease in the engine room to stubborn residues in cargo holds, traditional cleaning often relies on long hours of manual scrubbing and heavy use of chemicals.

This approach comes with obvious downsides: inconsistent cleaning results, higher risks to crew safety, increased costs, and environmental burdens from chemical discharge. For ship operators seeking safer, faster, and more sustainable ways to maintain high standards, mobile high-pressure cleaning presents a smarter alternative.

The hidden challenges of manual cleaning

The daily cleaning routines onboard a vessel demand both time and manpower. Crew members frequently work in difficult-to-reach areas, using brushes, scrapers, and strong detergents to tackle stubborn contaminants. This poses several challenges:

- Time and resource intensive: manual scrubbing can take hours, reducing available manpower for other critical tasks.

- Crew safety risks: physical strain, slippery surfaces, and exposure to harsh chemicals increase the likelihood of fatigue and accidents.

- Inconsistent results: manual methods often leave behind residues, affecting inspection readiness and operational reliability.

- Environmental footprint: heavy reliance on strong cleaning agents contributes to chemical runoff and disposal concerns.

These challenges highlight the need for solutions that deliver more consistent cleaning results while safeguarding both people and the environment.

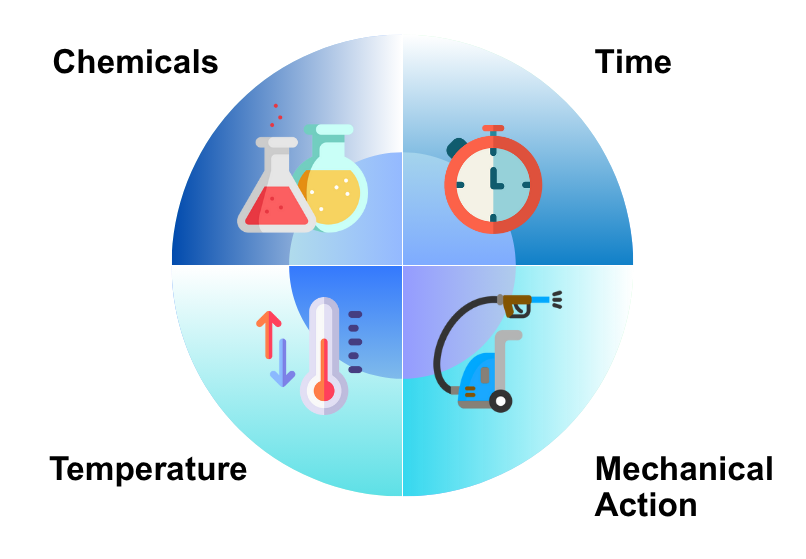

The science behind effective cleaning: Sinner's Circle

In the 1950s, chemical engineer Herbert Sinner described a theory that has since become the foundation of modern cleaning science: Sinner's Circle. It identifies four interdependent factors that influence cleaning effectiveness:

1. Chemical action (detergents, solvents, or cleaning agents)

2. Time (the duration of cleaning activity)

3. Mechanical action (scrubbing, pressure, or force applied)

4. Temperature (heat applied during cleaning)

In traditional shipboard cleaning, crews have typically compensated for limited mechanical action by relying heavily on time and chemicals. While effective to some extent, this balance introduces safety, cost, and sustainability issues.

High pressure cleaning changes this equation. By maximising the mechanical action element through the use of pressurised water to remove dirt, oil, and scale, the need for strong chemicals and prolonged scrubbing is significantly reduced. Temperature becomes less critical, and time spent cleaning is cut down. In other words, high pressure cleaning optimises the Sinner Circle to deliver better results with less risk.

Why high-pressure cleaning is a smarter alternative

The benefits of shifting from manual methods to high pressure cleaning are clear and measurable:

- Efficiency: cleaning times are reduced, allowing crews to complete tasks quickly and reallocate time to more critical duties.

- Versatility: high pressure systems can be deployed in cargo holds, engine rooms, machinery spaces, decks, and even external surfaces.

- Reduced chemical reliance: in many cases, water pressure alone is sufficient to remove contaminants, reducing chemical costs and discharge concerns.

- Sustainability: with fewer chemicals and lower reliance on heated water, the environmental footprint of cleaning is minimised.

- Crew safety: less manual scrubbing reduces fatigue, while fewer chemicals lower exposure risks.

For ship operators, these benefits translate into safer working conditions, reduced operational costs, and improved readiness for inspections.

On board applications of high-pressure cleaning

One of the strengths of high-pressure cleaning is its adaptability across a wide range of shipboard environments.

• Deck Maintenance

Clears oil spills, loose paint, marine growth, and surface contamination to ensure safe footing and prepare surfaces for recoating.

• De-Rusting & Surface Preparation

Removes loose rust and old coatings from steel surfaces before painting. Supports corrosion control routines and extends the life of exposed structures

• Engine Room & Machinery Spaces

Cuts through grease, fuel residues, and carbon deposits, improving safety by reducing fire hazards and maintaining clean work areas.

• Tank Cleaning

Removes rust scale, sludge, and biofouling to prepare tanks for inspection, cargo changeover, and compliance requirements.

• Cargo Holds

Cleans dry and wet cargo residues between operations, ensuring holds are clean, odor-free, and ready for the next cargo without contamination.

Whether for routine maintenance or turnaround cleaning between operations, high pressure cleaning machines provide flexibility that aligns with the dynamic needs of life at sea.

Safety, compliance, and long-term value

The adoption of high-pressure cleaning is not simply about convenience, but about aligning vessel operations with broader industry priorities.

- Regulatory compliance: thorough cleaning supports IMO requirements, port state inspections, and charterer audits.

- Asset longevity: by minimising abrasive manual methods, coatings and surfaces are preserved, extending their service life.

- Crew wellbeing: reduced chemical exposure and manual strain contribute to healthier, safer working environments.

- Operational readiness: faster and more consistent cleaning ensures vessels remain inspection-ready and operationally reliable.

The future of shipboard cleaning

The shipping industry is undergoing a transformation driven by decarbonisation, digitalisation, and a sharpened focus on crew welfare. Cleaning practices are no exception. As the industry continues to move towards greener and safer standards, such methods will likely become the new baseline for shipboard maintenance.

High pressure cleaning represents a clear step forward in how the maritime industry approaches one of its most essential yet overlooked routines. By harnessing mechanical cleaning power, ship operators can reduce reliance on chemicals, cut cleaning times, and create safer working conditions for their crew.

Discover more about high-pressure cleaning and the different solutions we have to help you get started here in our brochure:

特色供应

-

货舱清洗,做得更好

船东和船舶经营人要求更高效的压力越来越大。船舶装载不同货物时的洗舱至关重要,现在,洗舱比以往任何时候都受到更严格的管制。不符合规定的代价很高,会造成船舶在港口被滞留,直至符合规定。

-

全球提供标准舱柜清洗解决方案

虽然货物的种类和以往一样广泛,但对舱柜清洁要求的标准却在不断提高。这就是为什么我们构建了我们的全球网络,包括在世界关键位置建立15个专用油舱清洗港口。

-

在不降低安全和质量的情况下降低厨房和生活区的清洁成本

这是利用我们标准的厨房和生活区清洁产品的优势。

Articles you might be interested in

-

Exploring Marine Product Standards: The Nordic Swan Ecolabel

Amidst the growing demand for transparency and authenticity in the product lifecycle, uncover the ecolabel's profound significance in ensuring environmental stewardship that empowers you to make conscientious and sustainable choices

威尔森观察 |

Shirin Fanaian, Product Manager Chemicals – Cleaning -

Safeguarding clean drinking water for vessel crew

Addressing a wide range of contaminants, from sediments to microorganisms, find out how the Aquafilter safeguards crew health and well-being.

威尔森观察 |

Omar Labib, Product Manager, Cleaning Solutions -

Smarter Sewage Treatment with Probiotic Cleaners

Regulations for the prevention of pollution by sewage were laid down in Annex IV of MARPOL. This article will explore the features of probiotic cleaners, their uses and how they aid the treatment of waste aboard ships.

-

Protecting and promoting seafarer health in the maritime eco-system

Seafaring has always been considered a dangerous occupation. The crews of merchant ships are exposed to extremes of weather, operational hazards and dangerous cargoes to say nothing of the risks from serious casualties. But while the focus of loss prevention and safety initiatives is rightly on protecting seafarers from physical accidents, the risks to health from shipboard infections are an ever present danger.

威尔森观察 |

Jan Fredrik Bjorge, Technical Sales Manager Cargo Hold Cleaning and Tank Cleaning